Quality control for non-stick cookware is critical for ensuring product safety, durability, and performance. Inspection protocols focus on verifying coating thickness, cross-cut adhesion, and abrasion resistance. These tests are essential for confirming that kitchenware meets rigorous safety standards and can withstand daily use without peeling or releasing harmful substances. For manufacturers and retailers, adhering to these inspection methods is key to maintaining brand reputation and consumer trust.

Key Takeaways

- Regular inspection of non-stick cookware ensures safety and durability, protecting users from health risks and product defects.

- Understanding coating thickness is crucial; optimized thickness enhances performance and lifespan.

- The 3M Tape Test effectively checks adhesion, ensuring non-stick coatings remain intact during use.

- Abrasion resistance testing helps select durable coatings that withstand daily wear.

- Compliance with international standards like FDA and EN 12983-1 is mandatory for market access.

Non-Stick Cookware Inspection Essentials

Why Inspection Matters

Inspection plays a vital role in the kitchenware industry, particularly for Hardline Products. Quality control services focus on the integrity of the non-stick layer, preventing common defects like peeling, scratching, or uneven application. This process also mitigates health risks associated with harmful substances like PFOA or excessive heavy metals migrating into food.

| Category | Common Defects |

|---|---|

| Appearance | Scratches, dents, uneven finishing, discoloration |

| Material | Inconsistent coating thickness, peeling, rust |

| Functional | Uneven heating, loose handles, poor lid fit |

Key Testing Standards

Quality testing follows international benchmarks. These standards guide inspection teams during pre-shipment inspection and laboratory testing.

| Standard | Region | Focus |

|---|---|---|

| FDA 21 CFR | USA | Chemical safety & migration limits |

| EN 12983-1 | Europe | Performance & heat resistance |

| LFGB | Germany | Toxicity & food contact safety |

| GB 4806 | China | Coating migration & toxicity |

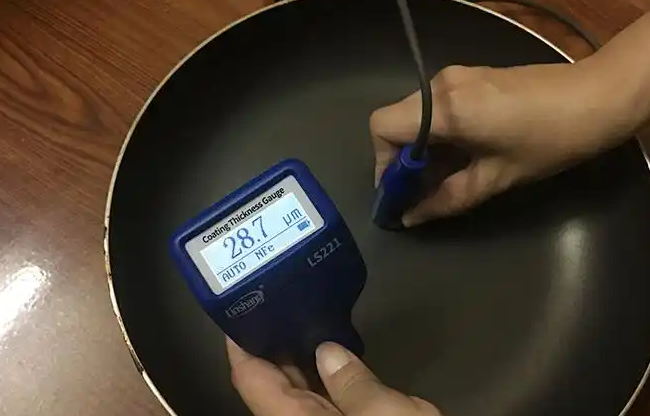

Coating Thickness Measurement in Cookware

Thickness and Performance

The thickness of the non-stick coating directly impacts performance. A thicker, multi-layer coating provides a robust barrier against wear, extending the product's life. Thinner coatings may wear out prematurely, leading to food sticking and potential metal exposure. Balancing thickness for durability and heat transfer efficiency is a key QC metric.

Measurement Methods

Inspectors use specialized gauges to measure coating thickness non-destructively. The most common methods are magnetic induction (for steel bases) and eddy current (for aluminum bases).

| Technique | Reliability | Application |

|---|---|---|

| Magnetic Induction | High | Ferrous substrates (Steel/Iron) |

| Eddy Current | High | Non-ferrous substrates (Aluminum) |

| Destructive (Cross-section) | Definitive | Laboratory analysis for disputes |

Cross-Cut Adhesion (3M Tape Test)

Adhesion Test Purpose

The cross-cut adhesion test validates the bond strength between the coating and the metal substrate. Poor adhesion leads to flaking and peeling, which poses health risks and ruins the cooking experience. This test ensures the coating can withstand thermal expansion and mechanical stress.

3M Tape Test Procedure

The 3M Tape Test (ASTM D3359) is the industry standard for checking adhesion:

- Cut: Create a grid of parallel cuts through the coating to the metal base using a specialized cutter.

- Apply: Place pressure-sensitive tape (e.g., 3M 600 or 610) over the grid.

- Remove: Pull the tape off rapidly at a 180-degree angle.

- Evaluate: Inspect the grid for any detached coating squares.

To pass, the coating must remain intact. If squares lift off, the batch fails, indicating issues with surface preparation or curing.

Abrasion Resistance Testing

Why Abrasion Resistance Matters

Cookware faces daily friction from spatulas, cleaning sponges, and stacking. Abrasion resistance testing simulates this wear to predict lifespan. High-quality coatings, often reinforced with ceramic or titanium particles, maintain their non-stick properties significantly longer than standard finishes.

Testing Techniques

Common laboratory tests include:

- Reciprocating Abrasion Test: A weighted pad (e.g., Scotch-Brite) rubs the surface back and forth for thousands of cycles until the substrate is exposed.

- LGA Shake Test: Simulates the abrasion caused by food and utensils during cooking agitation.

Implementing rigorous quality control for non-stick cookware—focusing on coating thickness, adhesion, and abrasion resistance—is essential. Manufacturers who prioritize these inspections deliver safer, longer-lasting products, reducing returns and building a reputation for reliability.

FAQ

What is the 3M Tape Test?

It is a standard adhesion test where a grid is cut into the coating, tape is applied and ripped off to see if the coating peels away from the metal base.

How does coating thickness affect quality?

Proper thickness ensures durability and scratch resistance. Too thin, and it wears out fast; too thick, and it may crack or affect heat distribution.

Why is abrasion resistance important?

It determines how long the pan stays non-stick. High resistance means the pan can withstand metal utensils and cleaning pads without losing its function.

Can I inspect cookware at home?

You can do visual checks for scratches or peeling. However, thickness and adhesion tests require specific tools and are best left to professionals.

What standards govern cookware QC?

Key standards include FDA (US), LFGB (Germany), and EN 12983-1 (Europe) for performance and safety.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.