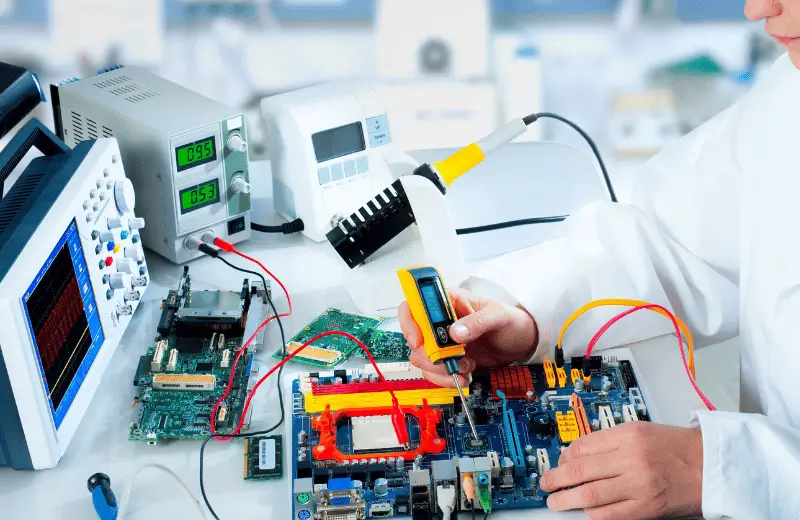

Electrical & Electronic Products Testing

Confirming safety, performance & compliance via advanced lab testing

Definition of Testing

Testing is a systematic service in the business ecosystem centered on data-driven value verification. It refers to a business activity where professional institutions or qualified entities conduct quantitative/qualitative analysis, verification and evaluation on the characteristics, indicators, compliance or quality level of objects such as products, materials, environments, services and processes. This is achieved by applying standardized procedures, professional equipment and technical means in accordance with national/industry standards, contractual agreements or customized requirements. Finally, a testing report with credibility is issued to provide core support for business decision-making, risk control, market access, quality assurance and trust building.

Testing Process

Needs Alignment: Clarify testing objects/projects/standards, confirm cycle/cost, and formulate testing plans.

Sample Management: Receipt verification, unique identification and traceability, preparation and standardized storage.

Testing Implementation: Equipment/environment calibration, standardized operation, parallel verification and abnormal handling.

Data Processing and Result Determination: Data collation and review, compliance determination against standards.

Report Issuance: Report compilation, multi-level review and compliant issuance.

Delivery, Filing and Follow-up Services: Report delivery, data filing, objection handling and consultation.

Electrical & Electronic Products Testing

1. Product Categories: Electronics, electrical appliances, lighting fixtures, consumer electronics, power adapters, etc.

2. Testing Standards: GB, ISO, ASTM, BS, EN, AS, AATCC, JIS, DIN, etc.

3. Common Testing Items:

• Basic Electrical Testing: Withstand voltage testing, insulation resistance testing, grounding resistance testing, etc.

• Operational Safety Testing: Overload protection, short-circuit protection, leakage current testing, etc.

• Emission Testing: Radiated emissions testing, conducted emissions testing, etc.

• Immunity Testing: Electrostatic Discharge (ESD) immunity, surge immunity testing, etc.

• Energy Efficiency Testing: Standby power consumption testing, etc.

• Thermal Performance Testing: Enclosure and component temperature rise testing, etc.

• Mechanical and Environmental Testing: Enclosure impact resistance, high-low temperature cycle testing, etc.

• Fire Performance Testing: Glow wire testing, needle flame testing, wire combustion testing, etc.

• Restricted Substance Testing: Lead, cadmium, mercury, hexavalent chromium, Polybrominated Biphenyls (PBBs), Polybrominated Diphenyl Ethers (PBDEs), phthalates.

• Interface and Label Testing: Plug and socket compatibility testing, label inspection, CE marking, UL certification marking, etc.