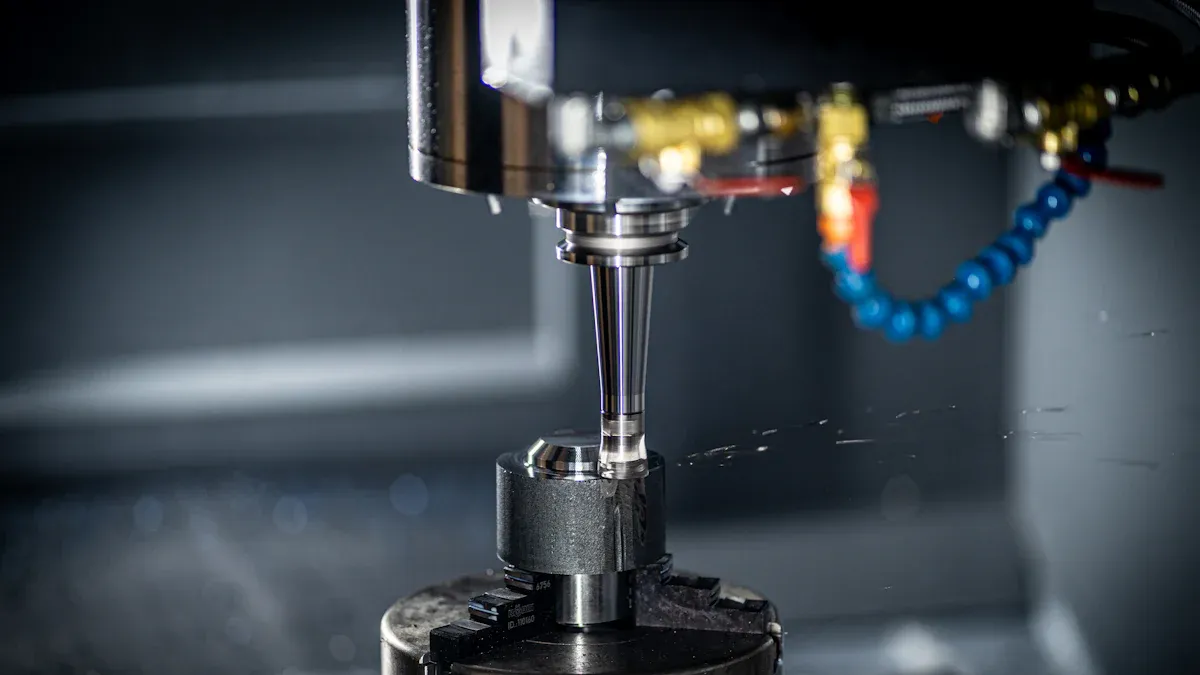

In the high-stakes sectors of aerospace, medical device manufacturing, and industrial engineering, the structural integrity of mechanical components is non-negotiable. Verification of CNC machining precision and heat treatment capabilities requires a comprehensive technical audit that transcends simple visual checks. A structured audit must evaluate the factory's metrological traceability, metallurgical process control, and adherence to international standards such as ISO 2768 and AMS2750. By analyzing process control charts, raw material certifications, and the implementation of corrective actions, stakeholders can mitigate risks before the first production unit leaves the assembly line.

Key Takeaways

- Factory audits serve as the primary technical gatekeeper for CNC precision and heat treatment consistency.

- Dimensional integrity is validated through ISO 2768 standards and Coordinate Measuring Machine (CMM) analysis.

- Heat treatment reliability is governed by pyrometric controls (TUS/SAT) and metallurgical hardness mapping.

- Specialized industries require Nadcap or IATF 16949 certified quality management systems for high-reliability components.

The Framework of a Precision Manufacturing Audit

A technical audit for precision manufacturing is designed to evaluate a supplier's "Process Capability" (Cpk). This metric determines whether the factory can consistently produce parts within specified tolerances over a long production run. Auditors verify the calibrated state of on-machine inspection systems and ensure that the metrology lab maintains a stable, temperature-controlled environment, which is critical for measuring micron-level tolerances.

Evaluation Protocol

| Audit Category | Technical Focus | Objective Data Points |

|---|---|---|

| Process Audit | Workflows and CNC programming | G-code validation, tool life monitoring |

| Quality Audit | QMS Compliance (ISO 9001) | SPC charts, calibration logs, MTRs |

| Metallurgical Audit | Heat treatment parameters | TUS/SAT records, quench rate analysis |

| Product Audit | Finished component fidelity | CMM reports, surface roughness (Ra) |

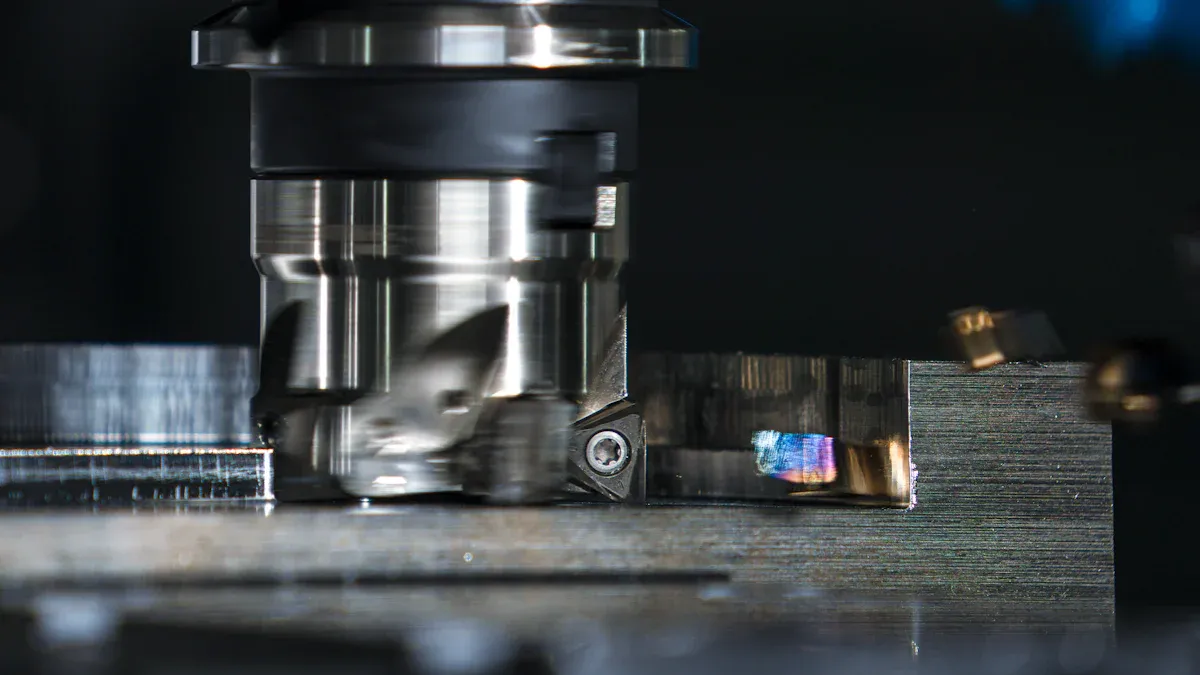

CNC Machining Precision: Dimensional and Geometric Tolerances

Precision CNC machining is the core of modern industrial parts production. Evaluating this capability involves more than checking if a part "fits." It requires a deep dive into "Geometric Dimensioning and Tolerancing" (GD&T). For critical applications, tolerances can be as tight as +/- 0.0025mm. Achieving this requires high-rigidity machine tools and sophisticated thermal compensation software.

Verification through Metrology

The Coordinate Measuring Machine (CMM) is the gold standard for dimensional accuracy. Auditors verify that the CMM is programmed correctly and that its ruby-tipped probes are calibrated. In high-volume orders, Statistical Process Control (SPC) is utilized to monitor trends. If the process mean shifts, the SPC system triggers an immediate adjustment to the machining parameters to prevent out-of-tolerance waste.

Heat Treatment Capabilities and Pyrometric Control

Heat treatment transforms the molecular structure of metal to achieve specific hardness, tensile strength, and fatigue resistance. However, it is an invisible process; a part may look perfect but be dangerously brittle or too soft. Auditing these capabilities requires verifying the factory's "Pyrometry" standards—the science of temperature measurement.

AMS2750 and Nadcap Requirements

In industries like aerospace, heat treatment must comply with AMS2750. This requires frequent Temperature Uniformity Surveys (TUS) to ensure that every corner of the furnace maintains the same temperature, and System Accuracy Tests (SAT) to verify that the thermocouples are reading correctly. Auditors check for representative sample jobs, where test bars (coupons) are treated alongside the production parts and then subjected to destructive tensile and Charpy impact testing.

| Test Type | Material Property Evaluated | Standard Instrument |

|---|---|---|

| Rockwell C (HRC) | Macro-hardness / Wear resistance | Rockwell Hardness Tester |

| Vickers (HV) | Micro-hardness / Case depth | Micro-indentation Tester |

| Tensile Test | Ultimate Yield Strength / Elongation | Universal Testing Machine (UTM) |

| Charpy V-Notch | Fracture Toughness / Impact energy | Pendulum Impact Tester |

The Role of Material Science in Precision Manufacturing

Reliable CNC machining and heat treatment depend on the initial material quality. Auditors verify the "Heat Lot" traceability and review Material Test Reports (MTRs) to confirm the chemical composition (e.g., Carbon, Manganese, Chromium levels). For high-performance alloys like Titanium or Inconel, specialized metallurgical analysis is required to check for "Alpha Case" surface contamination, which can cause catastrophic fatigue failure in rotating components.

Frequently Asked Questions (FAQ)

What is the difference between ISO 2768-m and ISO 2768-f?

These denote the tolerance classes for linear and angular dimensions. "m" stands for medium tolerances, while "f" stands for fine tolerances. In precision CNC machining, the "f" (fine) or even custom tolerances defined in ISO 2768-K are typically required for critical mating surfaces.

Why is TUS (Temperature Uniformity Survey) important in heat treat?

Furnaces can have hot or cold spots. If a TUS is not performed, some parts in a batch might be perfectly treated while others are under-quenched or over-tempered, leading to inconsistent mechanical properties across a single shipment.

How can I verify the accuracy of a factory's inspection report?

Utilize an independent third-party service like TradeAider product inspection. Our inspectors perform "re-measurement" on a sampled basis using calibrated tools to cross-reference and validate the factory's internal data.

What is Case Hardening vs. Through Hardening?

Case hardening (like carburizing) creates a hard, wear-resistant outer layer while maintaining a ductile, tough core. Through hardening ensures the entire cross-section of the part has uniform hardness. The choice depends on whether the part needs impact resistance or purely surface wear protection.

Does a CMM report guarantee a part will function correctly?

A CMM verifies "form" and "dimension." However, functional performance also depends on material integrity (heat treat) and surface finish. A complete quality assessment must integrate metrological, metallurgical, and functional test data.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.