Preface

In the footwear and apparel industry, quality control serves as the cornerstone for brand reputation and consumer loyalty. With the intensifying competition in the global market and the increasing demand for product quality from consumers, ensuring that every product meets high-standard quality requirements has become the primary task for footwear and apparel manufacturers.

As a third party institution independent of production and sales processes, third party inspection services play the role of quality guardians. Through professional and objective testing and evaluation, they assist manufacturers in identifying and correcting quality issues during production, ensuring product quality and enhancing market competitiveness.

Definition and scope of third party inspection companies

definition

A third party inspection company refers to an entity independent of two interconnected parties, such as the producer and the consumer. These companies or institutions conduct comprehensive inspections of products, services, systems, etc., through fair, independent, and professional means, and issue authoritative reports. With their professional technical expertise, rigorous inspection processes, and advanced inspection equipment, they provide quality assurance for products, ensuring that their safety, reliability, and performance comply with relevant regulations and standards.

Service scope

The service scope of third party inspection companies is extensive, covering multiple industries such as industry, agriculture, food, environment, and medicine. Specifically, it includes but is not limited to:

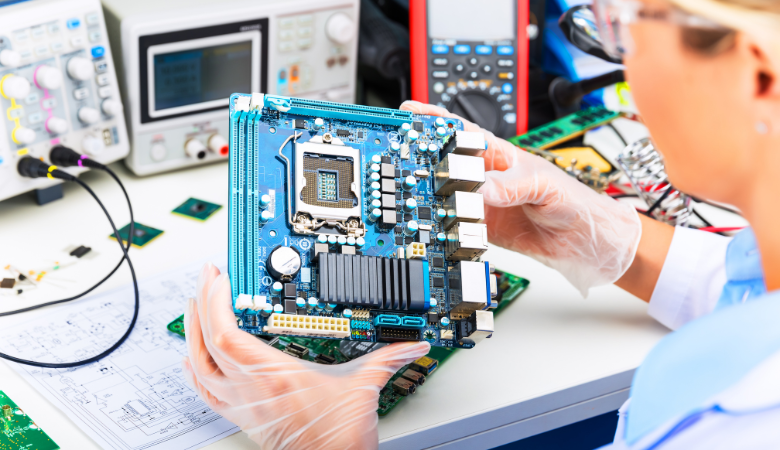

Industrial field: including raw material testing, product quality testing, equipment performance testing, etc. For example, testing the chemical composition and mechanical properties of steel, testing the electromagnetic compatibility and safety of electronic products, etc.

In the field of food: detecting the nutritional components, additives, pesticide residues, heavy metal content, etc. of food to ensure its safety and hygiene.

Environmental field: Conducting tests on environmental elements such as air, water, and soil to assess environmental quality. Testing items include pollutant concentration, noise, radiation, etc.

Pharmaceutical field: Testing the quality, purity, effectiveness, etc. of drugs to ensure they meet national drug standards.

Benefits of using third party inspection companies for footwear and apparel manufacturers

The benefits of footwear and apparel manufacturers utilizing third party inspection companies are primarily manifested in the following aspects:

Ensure product quality meets standards: third party inspection companies can conduct comprehensive and objective testing on footwear and apparel products, ensuring that they comply with relevant national or international standards, as well as specific requirements of customers or the market. This helps manufacturers avoid economic losses and reputation damage caused by product quality issues.

Enhancing brand image and consumer trust: By obtaining certification and testing reports from third party inspection companies, footwear and apparel manufacturers can convey reliable product quality information to consumers, thereby enhancing brand image and consumer trust. Consumers tend to prefer brands that have undergone third party inspection and certification when purchasing products.

Optimizing production processes and improving efficiency: third party inspection companies not only provide testing services, but also offer improvement suggestions to manufacturers based on the testing results. This helps manufacturers optimize production processes, reduce scrap rates, and improve production efficiency and product quality.

Complying with international trade requirements: In international trade, many countries and regions require imported products to undergo third party inspection and certification. By utilizing the services of third party inspection service companies, footwear and apparel manufacturers can ensure that their products comply with international trade requirements and smoothly enter the international market.

Reduce risks and costs: By utilizing the services of third party inspection companies, footwear and apparel manufacturers can proactively identify and address product quality issues, thereby avoiding additional costs such as returns and compensation arising from product quality issues. Additionally, third party inspection companies can provide manufacturers with risk assessment and consulting services, assisting them in reducing operational risks.

Shoe and clothing manufacturers can benefit from using third party inspection service companies in various ways, including ensuring product quality, enhancing brand image, optimizing production processes, complying with international trade requirements, and reducing risks and costs. Therefore, selecting a professional third party inspection service company is crucial for shoe and clothing manufacturers.

Explanation of key components of third party inspection

Prenatal examination

The primary step of pre-production inspection is material verification, which is crucial as it directly affects the smoothness of subsequent production processes and the stability of product quality. third party inspection companies conduct rigorous quality inspections on all incoming raw materials, including but not limited to fabrics, accessories, and threads, to ensure they meet established quality standards and specifications. Through this step, production delays and cost wastes caused by raw material quality issues can be effectively avoided, laying a solid foundation for source control of product quality.

Sample approval is another crucial aspect of pre-production inspection. During this stage, a third party inspection company will conduct a comprehensive and meticulous review of the sample's design, material, and craftsmanship based on the sample or design drawings provided by the client. Through comparison and analysis, it ensures that the sample fully meets the client's expectations and requirements, providing accurate reference and basis for subsequent mass production. This step not only helps reduce changes and rework during the production process but also enhances client satisfaction and boosts the brand's market competitiveness.

Inspection during production

During the production process, a third party inspection company will dispatch professional inspectors to the front line of production to strictly monitor and inspect each production step. From cutting and sewing to ironing and packaging, every detail cannot be overlooked. Through process control inspections, deviations and deficiencies in the production process can be promptly identified and corrected, ensuring strict implementation of production processes and steady improvement in product quality.

Online quality monitoring is another crucial means of inspection in production. With the aid of advanced testing equipment and technology, third party inspection companies are capable of real-time monitoring of product quality on the production line, encompassing key indicators such as size, color, and sewing quality. Upon detecting any anomalies, inspectors will promptly communicate with the person in charge of the production line to adjust production parameters in a timely manner, ensuring that product quality remains at its optimal level at all times.

Final inspection and pre-shipment inspection

During the final inspection and pre-shipment inspection stage, the third party inspection company will first conduct a comprehensive review and evaluation of the factory's production capacity and quality management system. Through on-site inspections, document reviews, and other methods, it ensures that the factory has stable production capacity and a sound quality management system, providing strong support for the smooth production and quality assurance of products.

Finished product inspection is the last line of defense to ensure product quality. third party inspection companies conduct rigorous sampling inspections on each batch of finished products, covering multiple aspects such as appearance, size, and performance. Only products that have undergone strict inspection and meet the shipping standards are allowed to be shipped for sale. This step effectively prevents the outflow of unqualified products, protecting the rights and interests of consumers and the reputation of the brand.

In addition to inspecting the finished products themselves, the third party inspection company will also verify the packaging and labeling of the products. This includes the selection of packaging materials, the reasonableness of packaging methods, and the accuracy of label information. This ensures that each product can be presented to consumers in its best condition, enhancing brand image and consumer satisfaction.

The key components of third party inspection - prenatal inspection, in-process inspection, final inspection, and pre-shipment inspection - jointly form a complete chain of product quality control. Through strict control, real-time monitoring, and meticulous verification, we ensure that every product meets or even exceeds consumer expectations, laying a solid foundation for the long-term development of the brand.