Quality control is very important in making shoes, especially when it comes to china shoes quality control. It ensures that every pair of shoes is well-made and liked by customers. Good quality control helps you gain trust and avoid mistakes. In Chinese factories, maintaining quality steady requires a clear plan. By focusing on shoe quality, you can create products that shine in a tough market.

.png)

Step 1: Define Quality Standards for Shoe Manufacturing

Establish Product Specifications

Start by clearly describing what your shoes should be like. These details act as a guide for making the shoes. Include things like material, color, size, and design. For example, if you want strong soles, mention the material and thickness. Clear instructions help Chinese factories understand what you want and avoid mistakes.

A detailed product sheet keeps things consistent. When all shoes follow the same rules, they meet your quality needs. This is very important, especially for making many shoes at once.

Align Standards with Industry and Safety Regulations

Next, match your quality rules with industry and safety laws. Check the rules for the places where your shoes will be sold. Some countries have strict rules about chemicals in materials. Following these rules keeps your brand safe and builds trust with customers.

Think about global standards like ISO certifications. These show your shoes meet worldwide quality levels. Share these rules with your factory to make sure they follow them. Update your standards often to stay safe and competitive.

Tip: Make a checklist of all rules and share it with the factory team. This helps everyone stay organized during production.

Step 2: Pick Trustworthy Shoe Makers in China

Do Thorough Factory Checks

Choosing good shoe makers in China starts with a full factory check. This helps you see if the factory can meet your needs. Visit the factory yourself or hire someone you trust to inspect it. Look at their tools, how much they can produce, and work conditions. These things show if they can handle your orders well.

Check their licenses and certifications. These papers prove they follow local rules and industry standards. Ask for examples of past work to see if they’ve made shoes like yours before. A careful check helps you pick a factory that cares about quality and dependability.

Tip: Use a list during the check to cover key points, like how they store materials, fix machines, and keep workers safe.

Check If Suppliers Follow Quality Rules

Once you choose a factory, see if they follow quality rules. Start by looking at how they work. Ask how they check materials, watch production, and test finished shoes. Factories with strong systems usually make better products.

Ask for samples of their work to see their quality. Match these samples with your product details. If they meet your needs, it shows they understand your expectations.

Talk with the factory often. Share your quality rules and make sure they follow them. Use outside services to double-check their work. This lowers risks and builds trust with the factory.

Note: Factories that follow rules well often have stronger partnerships with clients.

Step 3: Use a Step-by-Step Inspection Process

Keeping shoe quality steady needs checks at every production step. Checking at different stages helps find problems early and keeps quality high.

Check Materials Before Production

Look at all materials before making the shoes. Check for flaws, uniformity, and if they match your needs. For example, make sure leather or fabric is strong and looks good. Say no to materials that don’t meet your rules.

Make a list to guide your checks. Add things like material thickness, color matching, and chemical safety. This step makes sure only good materials are used.

Tip: Talk with suppliers so they know your material quality needs.

Watch Quality During Production

Keep an eye on the making process to fix issues fast. Check each step, like cutting, sewing, and putting parts together. Look for problems like bad stitching, wrong sizes, or loose soles.

Set up checks at important steps. For instance, check shoe tops before adding soles. This stops small mistakes from becoming big ones.

Teach workers to spot and report problems while working. Their help keeps quality steady during production.

Inspect Finished Shoes

Carefully check finished shoes before sending them to buyers. Look for flaws, correct sizes, and if they work well. Test strength by bending or pressing on key parts.

Use a system to sort shoes. For example, label them as "pass," "fix," or "reject." This keeps quality strict and ensures only the best shoes go to customers.

Note: Write down final check results to find patterns and improve.

Step 4: Teach Factory Workers About Quality Control Steps

Create Training That Fits the Factory

Make training programs that suit your factory's needs. First, find out what workers need to learn. Some may need help checking materials, while others might need tips on final checks. Fixing these gaps helps everyone know their part in keeping shoes high-quality.

Use hands-on lessons to teach useful skills. Show how to spot flaws, measure materials, and follow rules. Use pictures, videos, and charts to make learning simple. Give workers written guides or checklists to use while working.

Update training often to include new methods or rules. This keeps workers ready for changes in shoe-making.

Tip: Pair new workers with skilled ones to help them learn faster and feel confident.

Build a Team That Cares About Quality

Help workers take pride in their work. Explain how their efforts affect the shoes and make customers happy. When they see their value, they'll care more about doing a good job.

Make sure each worker knows their tasks. For example, stitching workers should check for crooked seams. Reward those who meet quality goals. Rewards inspire others to do better too.

Have regular team talks about quality problems and fixes. Use these meetings to give feedback and celebrate wins. When workers feel included, they care more about keeping standards high.

Note: A happy workplace helps workers take responsibility and report issues without fear.

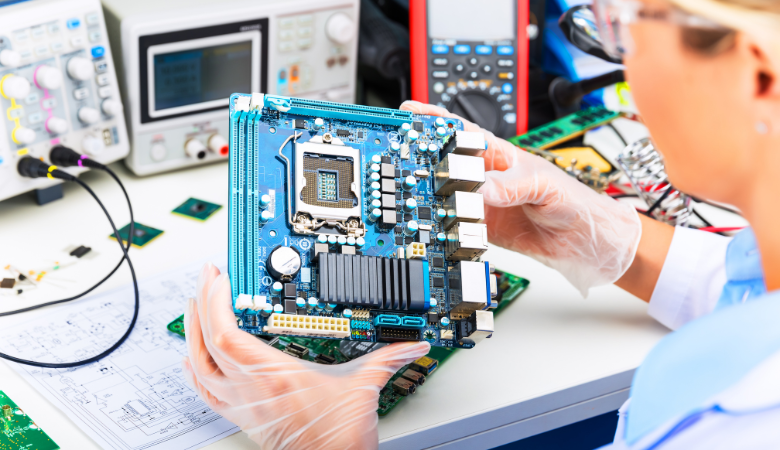

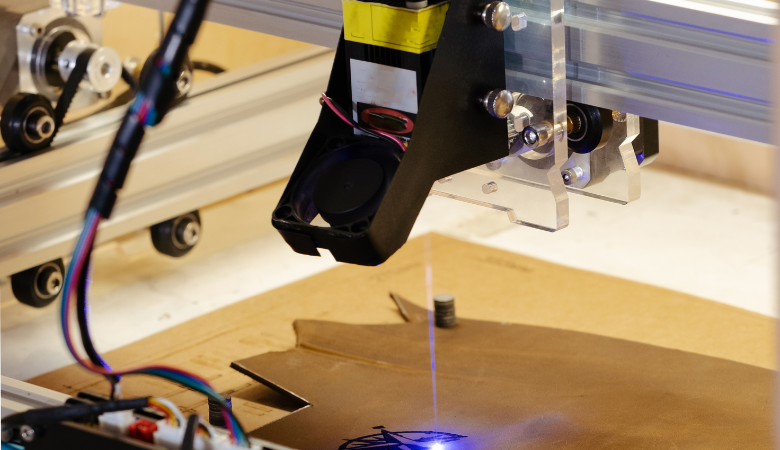

Step 5: Use Technology for China Shoes Quality Control

Try Automated Tools for Checking Shoes

Technology makes checking shoes quicker and more precise. Machines like laser scanners and vision systems find flaws better than people. These tools check sizes, spot surface issues, and ensure shoes match your needs. For instance, a vision system can find bad stitching or wrong colors that people might miss.

Machines also lower mistakes caused by humans. They work the same way every time and don’t get tired. Place these tools at key steps, like material checks or final reviews. This helps catch problems early and saves money.

Tip: Work with factories that already use smart inspection machines. This saves effort and improves quality.

Use Data to Spot Quality Problems

Data helps you see patterns and improve shoe quality. By studying inspection results, you can find common issues like weak stitching or bad materials. Fixing these problems at their source makes production better.

For example, if one material fails often, switch to a better supplier. Watching defect rates over time shows if the factory is improving or needs help.

Use software to sort and study inspection data. Many programs make charts and reports that are easy to understand. Sharing this info with your team helps everyone stay informed. Checking data often helps you make better choices and keep production smooth.

Note: Factories using data tools often make better products, helping your brand succeed.

Step 6: Keep Checking and Improving Quality Control Processes

Plan Regular Quality Checks

Quality checks find problems and make production better. Plan these checks often to keep standards high. During checks, review all steps, from materials to finished shoes. Look for issues like bad stitching, poor material care, or skipped inspections.

Make a list for checks. Add points like machine care, worker skills, and product quality. Use this list to make sure nothing is missed.

Hire outside inspectors for fair reviews. They can find hidden problems and suggest fixes. Share check results with the factory team to solve issues fast.

Tip: Use check results to set clear goals for improvement. For example, aim to lower defect rates by 10% next month.

Collect Feedback and Update Quality Rules

Feedback helps improve your quality control system. Get ideas from workers, inspectors, and customers. Workers can share production problems, and customers can talk about shoe performance.

Use surveys or talks to gather feedback. Ask about shoe strength, comfort, and looks. Study this info to find common problems.

Change your quality rules based on feedback. For example, if customers complain about weak soles, adjust material needs. Share these updates with the factory to ensure they follow new rules.

Note: Improving often keeps your products strong and earns customer trust.

Make feedback part of your routine. Plan monthly reviews to discuss findings and make changes. This active approach helps your shoes meet market needs.

Emoji Reminder: ��️ Use feedback to grow, not as criticism.

Making sure shoes are made well in Chinese factories needs a clear plan. By using these six steps, you can build a system that focuses on accuracy and trust. Each step helps improve the last, so you can make shoes that customers love.

Quality control isn't just a task; it's a smart choice. Keeping high standards protects your brand and keeps customers coming back. Make quality control a key part of your business to stay strong in the global market.

Reminder: Focus on quality now to succeed in the future.

TradeAider Third-Party Inspection Services

In conclusion, maintaining product quality and compliance is crucial for e-commerce sellers looking to succeed in a competitive market. Various solutions have been discussed, but one effective and reliable option is to partner with a third-party inspection service like TradeAider.

Ensuring Quality and Compliance Across Platforms

TradeAider's services are designed to provide consistent quality assurance, ensuring that products meet the stringent standards required by leading e-commerce platforms such as eBay. By partnering with TradeAider, sellers can avoid the pitfalls of non-compliance, maintaining a strong and reliable presence across all their sales channels.

Tailored Solutions for Enhanced Competitiveness

TradeAider's E-Commerce Quality Solutions are specifically crafted to empower sellers to enhance their product competitiveness through end-to-end quality control. Our services cover a wide range of product categories, including clothing, toys, 3C electronics, home goods, beauty and personal care, and household appliances. With a team of over 80,000 professional inspectors, we conduct thorough inspections on more than 30 core indicators, such as product appearance, functionality, packaging, and compliance. These inspections are based on the quality standards of e-commerce platforms and the regulatory requirements of target markets, ensuring that every product meets the highest standards from the supply chain to the consumer.

By choosing TradeAider, sellers can confidently navigate the complexities of e-commerce, knowing that their products are backed by rigorous quality control and compliance checks. This not only enhances product competitiveness but also builds trust with consumers, leading to long-term success in the e-commerce space.

FAQ

Why is quality control important in making shoes in China?

Quality control makes sure shoes meet your rules and please buyers. It stops mistakes, keeps products consistent, and builds trust in your brand. In China's busy shoe industry, good quality control helps you stand out.

How do you find trustworthy shoe makers in China?

Start by checking their papers and visiting their factories. Pick makers with shoe-making experience and good past work. Reliable partners make better shoes and keep production smooth.

How does technology help check shoe quality?

Technology makes checks faster and more exact. Machines find problems in materials and finished shoes. Data tools show patterns and help fix issues. Using tech improves quality and lowers mistakes.

How do you make sure factories follow your rules?

Work closely with factories and check their work often. Share your rules and watch how they make shoes. Regular checks and talks help keep quality high and meet your needs.

Why is China a smart choice for making shoes?

China has many top shoe factories and skilled workers. The country’s know-how in making shoes offers good quality at lower costs. This makes it a favorite for businesses worldwide.