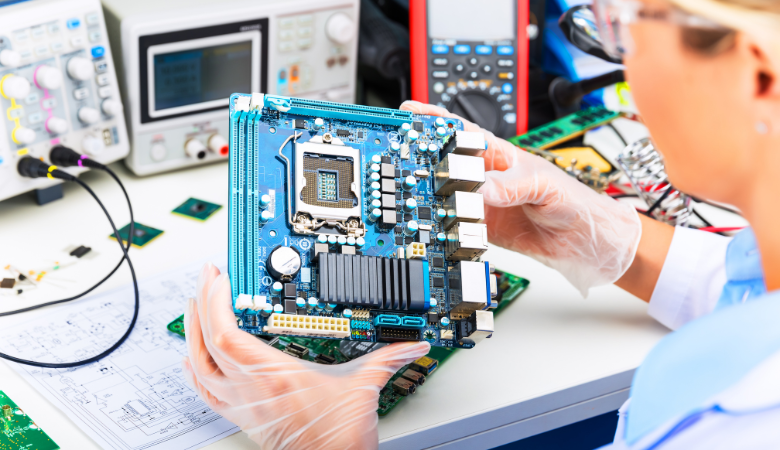

Quality control in electronicsindustry plays a crucial role in ensuring the success of production. Challenges such as defective components, flawed designs, and inadequate testing can disrupt manufacturing processes. These problems may lead to product failures, dissatisfied customers, and financial losses. Addressing these issues early ensures reliable products and enhances customer satisfaction. Identifying and resolving quality concerns promptly is essential to maintaining a competitive edge. Meeting high standards is vital in the electronics sector, and effective quality control in electronics industry is key to achieving success.

Common Challenges in Quality Control in Electronics Industry

Manufacturing Defects

Problems in making products often happen during production. These problems include things like bad soldering, parts not lined up, or unfinished assembly. They can happen because machines break or people make mistakes. Even small errors can cause big product failures. For example, a bad soldered joint might make a circuit stop working.

To lower these problems, keep production steps accurate and careful. Fix and check machines regularly to avoid mistakes. Also, check for problems at every step of making the product.

Tip: Use machines to watch production lines. Machines make fewer mistakes and keep work steady.

Component Reliability Issues

How well parts work is very important for products. Parts like capacitors, resistors, and microchips need to be high quality to work right. If a part breaks too soon, it can cost a lot to fix or replace.

Problems with parts can happen because of bad materials or wrong storage. For example, water can ruin delicate parts. To fix this, buy parts from trusted sellers and store them the right way.

Testing parts before using them is also a good idea. This helps you avoid putting bad parts into your products.

Note: Working with sellers who care about quality can help avoid part problems.

Testing and Inspection Limitations

Testing and checking are important to find problems and make sure products are good. But sometimes, these steps don't catch everything. You might miss problems because of old ways of checking. For example, looking at circuit boards by eye might not catch tiny issues.

To fix this, use better testing tools. Tools like automated optical inspection (AOI) and X-ray imaging can find hidden problems. These tools give better results and improve quality checks.

Alert: New testing tools can cost a lot, but they save money by stopping product problems and recalls.

Counterfeit Components and Material Quality

Fake parts are a big problem in the electronics industry. These parts may look real but don't work properly. Using fake parts can cause products to break, create safety issues, and cost money. It’s important to stop these parts from being used in production.

How Counterfeit Components Impact Quality

Fake parts can make devices fail or stop working. They might not last long, have wrong features, or use bad materials. For example, a fake capacitor could break during normal use and ruin the circuit.

Tip: Always check if parts are real before using them.

Strategies to Combat Counterfeit Components

You can avoid fake parts by doing these things:

• Source from Trusted Suppliers: Buy parts from sellers with a good reputation.

• Use Authentication Tools: Use tools like barcodes or holograms to check parts.

• Conduct Incoming Inspections: Inspect all parts when they arrive to ensure quality.

• Collaborate with Industry Groups: Join groups that fight against fake components.

Material Quality and Its Role in Quality Control

Good materials are key to making reliable electronics. Bad materials can cause overheating, rust, or short circuits. Always choose materials that meet standards and pass strict tests.

Spending more on good materials now saves money later by avoiding repairs.

By fixing issues with fake parts and bad materials, you improve quality control. These actions help your products work well and keep customers happy.

Effective Solutions to Quality Control Issues

Using Better Testing Tools

Modern testing tools find problems early and make products better. Old methods often miss hidden issues, but new tools work well. For example, AOI systems quickly check circuit boards for mistakes. X-ray imaging shows problems inside parts that you can't see.

Testing how products work in real life is also helpful. This checks if they meet customer needs. Testing in tough conditions, like heat or moisture, finds weak spots before selling.

Tip: Spend money on better testing tools to avoid recalls and keep customers happy.

Adding Automation and AI to Quality Checks

Automation and AI are changing how quality checks are done. Machines can do repeated tasks perfectly, lowering human mistakes. For example, robotic arms can put parts together with great accuracy.

AI tools study lots of data to find problems early. Machine learning can spot defects that old methods miss. For instance, AI can look at AOI images to find tiny cracks or misaligned parts.

Automation and AI also make production faster. You can make more products quickly without losing quality. This saves time and money over time.

Note: Start small by automating one task, then grow as you see success.

Managing Supplier Quality

Suppliers affect how good your products are. Bad parts from suppliers can cause problems in your products. To stop this, have a strong plan for managing supplier quality.

Pick suppliers with a history of giving good materials. Check them often to make sure they meet your rules. Share clear quality needs with suppliers to avoid confusion.

Build long-term partnerships with suppliers. Good relationships make them care about your needs and keep quality steady. Use a scorecard to rate suppliers on delivery, material quality, and response time.

Alert: Don't depend on one supplier. Use many sources to lower risks and get good parts regularly.

Continuous Employee Training and Skill Development

Your workers are key to keeping quality high. Without good training, even the best tools won’t work well. Regular lessons help your team learn new technologies and methods.

First, find out what skills your workers need to improve. For example, factory workers might need to learn how to use new testing machines. Engineers may need help with fixing problems or studying test results. Make training programs that fit these needs.

Tip: Use real-life examples and hands-on practice to make learning better.

Support a habit of always learning. Offer refresher classes and certificates to keep workers interested. You can also invite experts to give talks or online lessons. This builds skills and boosts confidence.

Check how well training works. Use numbers to see if workers improve after lessons. For example, track how many mistakes happen before and after training. This shows what’s working and what needs more focus.

By teaching your workers, you improve quality control. Skilled workers make fewer mistakes, fix problems faster, and create better products.

Adopting Flexible Quality Control Systems

Strict systems can't keep up with the fast-moving electronics world. You need flexible systems to handle new demands and challenges.

Start by using systems you can change easily. These let you add or remove tools as needed. For instance, if you launch a new product, you can add testing tools without changing everything.

Alert: Being flexible doesn't mean lowering standards. Always follow industry rules.

Cloud-based systems can also help. They let you watch production live, even from far away. This helps you find and fix problems quickly, saving time and improving work.

Clear steps for testing and checking also help. Write simple rules for inspections and reports. This keeps things steady but allows changes when needed.

Lastly, encourage teams to talk and share ideas. When workers share feedback, you can spot problems early and adjust plans.

Flexible systems help you stay ready for surprises. They keep quality high while meeting the changing needs of the electronics industry.

Preventative Measures for Long-Term Quality Assurance

Setting Clear Quality Rules

Strong quality rules help products meet customer needs. Start by making clear steps for every production stage. These steps should include picking materials, making products, and testing them. Use industry rules as a guide but adjust them for your needs.

Write down these rules and share them with your team. When everyone knows the rules, it’s easier to keep things steady. Update your rules often to match new tools or market changes.

Tip: Use simple lists during production to check each step follows your rules.

Checking Processes and Listening to Feedback

Regular checks find problems early. Look at your tools, steps, and materials often. These checks show where things can be better.

Ask workers for ideas. People working on products see problems others miss. Make it easy for them to share issues or ideas without fear.

Fix problems quickly after hearing feedback. Watch how changes work and improve over time. This cycle of checking, listening, and fixing makes quality control stronger.

Alert: Ignoring worker ideas can cause repeated problems and waste money.

Working Well with Suppliers

Suppliers are important for keeping quality high. Work with suppliers who focus on being honest and reliable. Check how well they do their job often to make sure they meet your needs.

Tell suppliers exactly what you want. Share rules for materials, delivery times, and certifications. When suppliers know your needs, they can give better results.

Use more than one supplier to avoid risks. If one supplier fails, others can help keep production going.

Note: Long-term deals with good suppliers lead to better teamwork and higher quality.

Standardizing Testing Protocols

Making testing rules the same helps keep checks reliable. Without clear steps, you might miss important problems or get uneven results. Following set rules improves product quality and lowers mistakes.

Why Standardized Testing Matters

Using the same testing steps for all products makes checks reliable. It helps find problems early and ensures every product is high quality. Standard rules also make training easier and allow comparing results between batches.

Tip: Keeping testing steady builds customer trust and avoids recalls.

Steps to Standardize Testing Protocols

1. Define Clear Testing Criteria

Write down what to test and how to measure success. For example, decide the voltage a circuit should handle or the heat a device can take.

2. Use the Right Tools

Pick tools that fit your needs. Machines like testers or heat chambers help keep tests accurate.

3. Create Step-by-Step Procedures

Split testing into simple steps. For example:

◦ Look at the product closely.

◦ Test how it works with electricity.

◦ Check how it performs under tough conditions.

4. Document Results

Write down test results in the same format every time. This helps spot trends and repeated problems.

5. Review and Update Protocols

Check often if your testing rules match industry needs. Change them when new products or tools are added.

Benefits of Standardization

Making testing rules the same builds strong quality control. It improves products and boosts your reputation in electronics.Skipping this step can cause uneven results and big mistakes.

Fixing quality control problems in electronics needs smart actions. Use new tools, strong methods, and always aim to improve. Better testing, using machines, and managing suppliers well can solve issues. Check quality at every step to stop mistakes early. This makes customers happy and helps your business succeed. Always work hard to keep high standards and stay ahead in this tough industry.

TradeAider Third-Party Inspection Services

Pre-Listing Quality Assurance

Before products are listed on e-commerce platforms,TradeAiderplays a crucial role in ensuring both quality and compliance. This step is vital for sellers to avoid potential issues such as product removal or suspension due to non-compliance. By leveraging TradeAider's services, sellers can confidently meet the stringent standards required by platforms like eBay.

Consistent Quality Across Channels

For sellers managing multiple sales channels, maintaining uniform product standards is challenging. TradeAider addresses this by providing consistent quality assurance services, ensuring that products meet the same high standards across different platforms. This consistency is key to building trust with customers and enhancing brand reputation.

Tailored E-Commerce Quality Solutions

TradeAider's E-Commerce Quality Solutions are specifically designed to empower sellers with end-to-end quality control. This comprehensive approach enables sellers to enhance the competitiveness of their products in the market. Our services are not limited to a few categories but cover a wide range of products, including clothing, toys, 3C electronics, home goods, beauty and personal care items, and household appliances.

Expert Inspection Team

With a team of over 80,000 professional inspectors, TradeAider conducts detailed inspections based on over 30 core indicators. These indicators include product appearance, functionality, packaging, and compliance. Our inspections are aligned with both e-commerce platform quality standards and the regulatory requirements of target markets. This ensures that every product is thoroughly checked at every stage, from the supply chain to the end consumer.

Enhancing Competitiveness

By integrating TradeAider's inspection services into your business plan, you can significantly enhance the competitiveness of your products. This not only helps in avoiding costly mistakes and potential sales disruptions but also builds a foundation of trust with your customers. TradeAider's commitment to quality ensures that your products stand out in a crowded e-commerce marketplace.

FAQ

What causes most quality control problems in electronics?

Production mistakes are the main cause of issues. These include bad soldering, parts not lined up, or unfinished assembly. Keeping machines in good shape and checking every step can lower these problems.

How can you make sure suppliers give good parts?

Work with reliable suppliers who meet your quality needs. Check their work often, inspect materials when they arrive, and use a scorecard to track how they do. Long-term partnerships help suppliers focus on quality.

Why is automation helpful for quality control?

Automation lowers human mistakes and gives steady results. Machines like robotic arms and AI tools find problems faster and better than people. This makes products more reliable and saves time.

How do fake parts hurt product performance?

Fake parts break easily or work poorly. They can cause safety problems and hurt your reputation. To stop this, buy from trusted sellers and use tools to check if parts are real.