Consumers expect their Ready-to-Assemble (RTA) furniture to be durable, safe, and easy to build. Quality control is pivotal in ensuring that flat-pack furniture meets these expectations. From verifying precise machining to checking the completeness of hardware kits, rigorous inspection protocols protect brand reputation and customer satisfaction. Key QC stages include assembly testing to confirm structural integrity, hardware verification to prevent missing parts, and chemical emission checks to ensure indoor air safety.

Key Takeaways

- Quality control in RTA furniture ensures safety and durability, enhancing customer satisfaction.

- Conduct thorough assembly testing to identify design flaws and ensure instructions are clear.

- Always verify hardware components against the packing list to prevent consumer frustration.

- Check for formaldehyde emissions to comply with safety standards like CARB and protect indoor air quality.

- Perform stability checks on assembled units to prevent tipping hazards.

Assembly Testing for RTA Furniture

Preparing for Assembly

Effective assembly testing begins with replicating the consumer's experience. Inspectors should use a clean, flat area and only the tools typically available to a home user. This process verifies that the provided instructions are accurate and easy to follow. Reviewing the manual beforehand helps identify potential confusion points that could lead to assembly errors.

Tip: During QC, assemble the product strictly according to the manual to catch any logical errors in the instructions.

Assembling RTA Cabinets

The assembly process involves checking the fit and finish of every component. Inspectors verify that pre-drilled holes align perfectly and that joints are secure without forcing. Key steps include attaching side panels, securing backboards, and installing drawer runners. Using the correct torque prevents damage to the particleboard or MDF material.

Stability Checks

Once assembled, stability testing is crucial. Inspectors apply pressure to various points to check for wobbling or structural weakness. Standards like EN 14749 and ISO 7170 provide guidelines for testing the strength and durability of storage units.

| Standard | Description |

|---|---|

| EN 14749 | Safety requirements and test methods for domestic and kitchen storage units. |

| ISO 7170 | Test methods for strength and durability of storage units. |

Ensuring the cabinet sits level and does not tip easily is a critical safety check, especially for tall units.

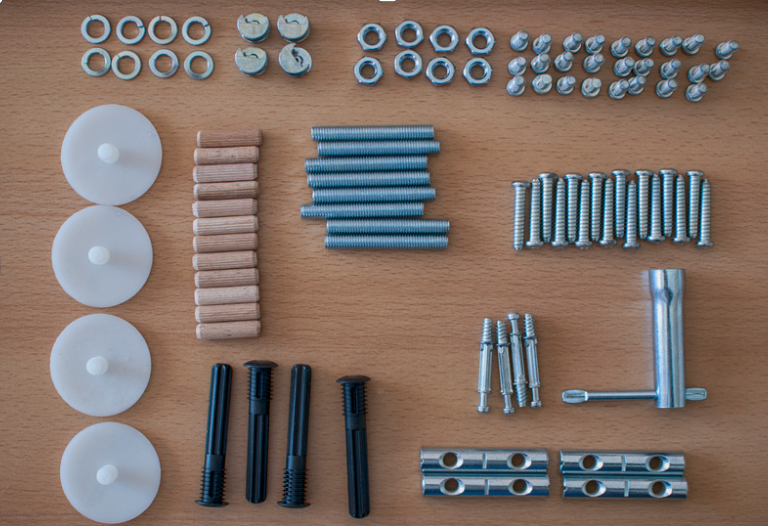

Hardware Kit Verification

Checking Hardware Components

Missing hardware is a top cause of consumer complaints. Hardware verification involves weighing and counting kits to ensure completeness. Inspectors spread out all parts and match them against the BOM (Bill of Materials). Sorting screws, dowels, and cam locks by type helps quickly identify discrepancies.

| Checklist Item | Action |

|---|---|

| Quantity Check | Count every screw and fastener against the manual. |

| Quality Check | Inspect for deformed threads or rusted parts. |

| Packaging | Ensure hardware bags are sealed and labeled correctly. |

Accessory Inspection

Accessories like handles, hinges, and shelf supports must also be verified. Visual inspection ensures finishes are consistent and free from scratches. Inspectors check that hinges operate smoothly and that handles align with pre-drilled holes.

Formaldehyde Emission Checks

Understanding Emission Standards

Composite wood products often use adhesives that release formaldehyde, a known irritant and carcinogen. Strict regulations limit these emissions to protect indoor air quality. Major standards include CARB (California Air Resources Board) Phase 2 and EPA TSCA Title VI. Compliance is mandatory for selling in major markets like the US and Europe.

Note: Verify that products carry the necessary certification labels indicating compliance with formaldehyde emission standards.

Testing Methods

Manufacturers and third-party labs use specific methods to measure emissions. The "Chamber Method" simulates real-world conditions, while the "Desiccator Method" provides a quicker assessment of emission levels.

| Method | Description |

|---|---|

| Chamber Method | Measures emissions in a climate-controlled chamber (ASTM E1333). |

| Desiccator Method | Measures formaldehyde released into water in a sealed vessel (ASTM D5582). |

Reducing Exposure

To meet these standards, manufacturers use low-emission resins (NAF or ULEF) and apply sealants or laminates that act as barriers. Proper ventilation of finished goods before packaging also helps dissipate residual emissions.

Comprehensive quality checks for RTA furniture are essential for reducing returns and building brand loyalty. By rigorously testing assembly, verifying hardware kits, and ensuring chemical safety, manufacturers can deliver products that are safe, reliable, and easy to use.

FAQ

How long does it take to assemble RTA panel furniture?

Assembly time varies by complexity, but most standard units take one to two hours. Clear instructions and organized hardware significantly speed up the process.

What should be done if hardware is missing?

Double-check packaging first. If parts are truly missing, contact the manufacturer's customer service for replacements.

Are formaldehyde emissions a concern with RTA furniture?

Yes, but certified RTA furniture meets strict safety limits. Airing out new furniture in a well-ventilated room helps reduce any initial odor.

Can beginners assemble RTA cabinets?

Yes, RTA furniture is designed for DIY assembly. With patience and adherence to the manual, beginners can successfully assemble these products.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.