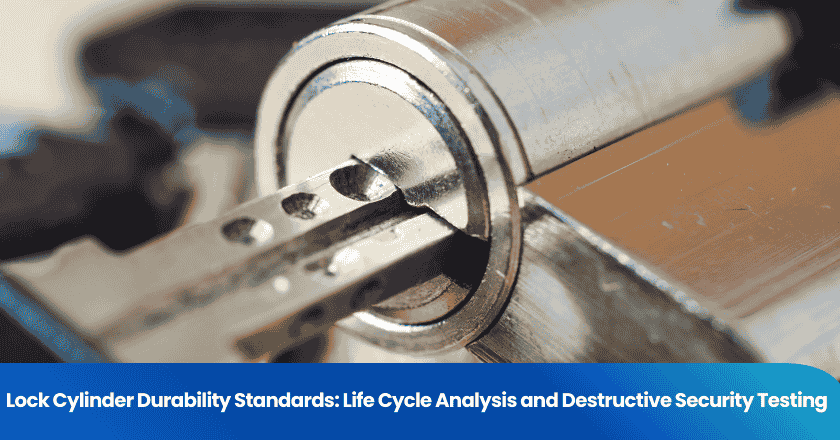

In the domain of physical security, the lock cylinder serves as the primary barrier against unauthorized ingress. Whether for high-traffic commercial facilities or private residences, the operational longevity and structural integrity of a cylinder determine the overall efficacy of a security system. A lock's lifecycle is not merely a measure of time, but a technical validation of mechanical fatigue life and resistance to environmental degradation. By adhering to rigorous anti-theft destructive testing protocols, manufacturers can ensure that their products withstand both stealthy picking attempts and violent forced entries. Understanding the engineering behind these standards is vital for architects, facility managers, and safety inspectors.

Key Takeaways

- Lock cylinder durability is quantified through cycle testing, with premium grades exceeding 100,000 operations.

- Mechanical performance is evaluated through material hardness and tensile strength analysis of pins and housing.

- Destructive testing simulates real-world criminal techniques, including drilling, snapping, and torque attacks.

- European (EN 1303) and American (ANSI/BHMA) standards provide the global framework for security classification.

- Regular quality control inspections and factory audits are essential to maintain consistent production quality.

- Strategic maintenance using dry-film lubricants significantly extends the operational lifecycle of complex mechanisms.

Mechanical Fatigue and Cycle Testing Protocols

Operational durability is the cornerstone of cylinder reliability. Fatigue testing involves automated machines that repeatedly insert a key, turn the plug to the locked and unlocked positions, and withdraw the key. The objective is to identify the point of mechanical failure—typically caused by the wearing down of the driver pins or the weakening of the phosphor bronze springs.

Industrial vs. Residential Cycle Standards

The technical requirements vary significantly based on the intended application. A residential lock may only experience 2,500 cycles over its life, whereas a lock in a commercial hospital or school might surpass that within a single month. To meet these demands, professional factory audits verify that the manufacturing process utilizes precision CNC machining to maintain tolerances within +/- 0.02mm, reducing friction and increasing cycle life.

| Standard Type | Grade/Category | Required Cycles | Typical Application |

|---|---|---|---|

| ANSI/BHMA A156.5 | Grade 1 (Heavy Duty) | 1,000,000 | Public Institutions, Airports |

| ANSI/BHMA A156.5 | Grade 2 (Medium Duty) | 400,000 | Commercial Offices |

| EN 1303:2015 | Grade 6 (Maximum) | 100,000 | High-Security Zones |

| EN 1303:2015 | Grade 4 | 25,000 | Residential Entry Doors |

Destructive Testing and Anti-Theft Engineering

While cycle testing measures "wear and tear," destructive testing measures "resistance to attack." High-security cylinders are engineered with specific "sacrificial" and "reinforced" components designed to frustrate attempts at forced entry. These tests are performed in controlled laboratory settings using high-torque tools and impact simulators.

Resistance to Drilling and Extraction

One common attack involves drilling out the pins to bypass the shear line. To counter this, engineers incorporate hardened steel inserts or tungsten carbide "anti-drill" pins within the cylinder body and plug. During standardized product inspections, testers measure the time required to penetrate these barriers. A Grade D (EN 1303) cylinder must resist a high-speed drill attack for at least 10 minutes of active tool time.

Cylinder Snapping and Torque Resistance

Cylinder snapping is a method where the protruding part of a Euro-profile cylinder is gripped and snapped at its weakest point (the screw hole). Modern anti-snap cylinders feature a pre-cut "snap line." When excessive force is applied, only the outer portion breaks off, leaving the internal locking mechanism intact and still operational from the inside. Torque testing involves applying rotational force (measured in Newton-meters) to the plug to ensure it cannot be sheared from the body.

| Attack Type | Technical Objective | Engineering Countermeasure |

|---|---|---|

| Drilling | Bypass pin shear line | Hardened steel ball bearings and plates |

| Picking | Manual manipulation of pins | Mushroom, Spool, or Serrated pins |

| Lock Bumping | Kinetic energy transfer to driver pins | Anti-bump dampers and weighted pins |

| Extraction | Pulling the plug or cylinder out | Reinforced bridges and locking cams |

The Physics of Surreptitious Attacks: Picking and Bumping

Not all attacks are destructive. Surreptitious entry involves manipulating the internal components without leaving visible signs of tampering. The most prevalent technical method is "Lock Bumping," which uses a specially cut key to transfer kinetic energy to the driver pins, momentarily clearing the shear line. High-purity high-security locks utilize non-magnetic pins or side-bar mechanisms that are immune to standard bumping and picking physics.

Expert Insight: The "Master Keying" of a building significantly increases its vulnerability to surreptitious attacks. Every additional "cut" on a pin increases the mathematical probability of a random key or a pick successfully clearing the shear line. Quality control must verify the key-coding matrix for security integrity.

Global Standards Comparison: EN 1303 vs. ANSI/BHMA

For global procurement, understanding the classification systems of different regions is essential. The European standard EN 1303 uses an 8-digit coding system to classify cylinders by durability, fire resistance, and security. In contrast, the US system by ANSI/BHMA focuses on a Grade 1 to Grade 3 scale, with Grade 1 representing the highest industrial tier.

A comprehensive quality assurance program must verify that the test data provided by a laboratory matches the physical attributes of the production batch. It is common for a "golden sample" to pass testing while the mass-produced units utilize lower-grade brass or lighter springs.

Technical Maintenance for Extended Longevity

Even the most robust cylinder will fail if it is subjected to environmental corrosion or particulate buildup. Maintenance should follow professional technical guidelines to prevent catastrophic failure:

- Avoid Petroleum-Based Oils: Lubricants like WD-40 or heavy oils attract dust and grit, forming a grinding paste that accelerates pin wear.

- Use Dry-Film Lubricants: PTFE (Teflon) or Molybdenum Disulfide sprays provide a low-friction surface that does not attract contaminants.

- Environmental Sealing: For outdoor cylinders, particularly in coastal areas, ensuring a high "Corrosion Resistance" rating (EN 1303 Category C) is mandatory to prevent internal oxidation.

- Key Integrity: Worn keys are a primary cause of cylinder failure. A key that has lost 0.05mm of its profile will struggle to lift the pins to the precise shear line, leading to intermittent jamming.

Integrating these maintenance practices with precise measurement and inspection ensures that the security infrastructure remains operational for its intended 10-15 year design life.

Frequently Asked Questions (FAQ)

What is the "sacrificial cut" in a lock cylinder?

A sacrificial cut is a deliberate weak point engineered into the cylinder body. If an intruder attempts to snap the cylinder, it breaks at this line rather than at the central cam. This ensures the internal locking mechanism remains secure and inaccessible to the intruder's tools.

Why do some cylinders feel "scratchy" when turning?

This is often a symptom of "burrs" left over from the machining process or a lack of proper lubrication. In high-quality inspected batches, the plug and pins undergo a deburring and polishing process to ensure a smooth, fluid movement.

How does a "restricted keyway" improve security?

A restricted keyway uses a proprietary profile that is not available on the open market. This prevents unauthorized key duplication at local hardware stores and complicates picking attempts, as standard picking tools may not fit the complex grooves of the keyway.

Can a lock be 100% pick-proof?

Technically, no lock is 100% pick-proof given unlimited time and technical expertise. However, high-security cylinders are "pick-resistant," meaning they are designed to take so much time and specialized skill to pick that an intruder is likely to be detected or discouraged.

How often should commercial lock cylinders be inspected?

In high-traffic commercial environments, a visual and functional inspection should be performed quarterly. A technical service—including cleaning and lubrication—should be conducted annually to mitigate the effects of mechanical fatigue.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.