The electronics industry is renowned for its rapid innovation, but this pace also poses challenges in maintaining high quality standards. Implementing effective quality control (QC) is crucial to ensure that products meet the required specifications, are safe, and reliable.

This article briefly explains the process of establishing quality control in electronic manufacturing, covering aspects such as standards, technologies, techniques, and challenges.

Quality control is crucial in the electronics industry, as defective products can pose serious risks to consumers and damage a company's reputation. By ensuring that products meet industry standards, manufacturers can enhance reliability, reduce recalls, and maintain consumer trust.

Many factors can affect the quality of electronic products, including raw materials, design specifications, production processes, and testing protocols. The QC system encompasses all these aspects, ensuring consistent quality from start to finish.

Understand quality control in the electronics industry

Definition of quality control in the electronics industry

Quality control in the electronics industry, as a crucial aspect of ensuring excellent quality and reliability of electronic products, encompasses a comprehensive and full-process monitoring and management system from raw material warehousing to finished product delivery. The system is committed to ensuring that every product meets predetermined quality standards. Through a series of carefully designed activities, it builds a solid defense line, effectively preventing any potential defects from entering the consumer market.

From the initial selection of raw materials to the delivery of final products, every step embodies the wisdom and sweat of quality control personnel. Specifically, the quality control process in the electronics industry can be subdivided into the following key stages:

Different types of quality control processes

Before production: The core task of this stage is to conduct comprehensive inspections and tests on the components and raw materials that are about to be put into production. Through rigorous screening and evaluation, it is ensured that only materials with stable performance and superior quality are allowed to enter the production line.

In production: When the production process is fully operational, quality control work enters a new phase. In this phase, quality control personnel will adopt real-time monitoring to observe and record every aspect of the production process. Any abnormalities or potential issues will be identified and measures taken to address them, ensuring that problems are nipped in the bud before they have a substantial impact on the final product.

Post-production: When the product successfully completes the production process and is about to embark on its journey to the market, quality control does not end here. On the contrary, quality control at this stage is particularly crucial. Post-production quality control mainly involves final inspection and testing of the finished product to ensure that all performance indicators of the product meet or exceed the predetermined quality standards.

Establish quality standards and guidelines

In the electronics industry, adhering to international standards and regulations is crucial for ensuring product quality and enhancing market competitiveness.

Industry standards and regulations (ISO, IEC, etc.)

Standards established by authoritative organizations such as ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission), including the ISO 9001 quality management system standard and the IEC 61000 electromagnetic compatibility standard, have become benchmarks that the electronics industry must adhere to. International standards provide manufacturers with a unified quality management framework, assisting them in ensuring consistency in product design, production, sales, and other aspects, and meeting regulatory requirements in the global market.

Define quality indicators and benchmarks

To measure product performance more specifically, manufacturers need to define clear and quantifiable quality indicators. Indicators serve as an important basis for evaluating the quality of products and may cover multiple aspects, such as failure rate, durability, reliability, safety, and customer satisfaction. By setting these indicators, manufacturers can gain a more intuitive understanding of product performance, promptly identify potential issues, and provide direction for continuous improvement.

While setting quality indicators, manufacturers also need to establish corresponding benchmarks. These benchmarks serve as the standard lines for determining the acceptable levels of indicators and represent the bottom line for product quality control. Only products that meet these benchmarks can be deemed qualified and allowed to be sold out of the factory. The establishment of benchmarks requires comprehensive consideration of multiple factors such as market demand, technical feasibility, and cost-effectiveness, to ensure that they not only meet consumer expectations but also align with the actual operational situation of the enterprise.

Customize standards for specific electronic products

While general standards are applicable to most electronic products, specific types of products may require more customized standards. Taking medical devices and consumer electronics as examples, these two types of products exhibit significant differences in terms of functionality, usage, and safety requirements. Due to their direct relevance to patient safety, medical devices are subject to stricter regulatory requirements and standards. When developing and producing medical devices, manufacturers must adhere to specific industry standards, such as relevant regulations for medical devices, to ensure the safety and effectiveness of the products.

Consumer electronics products, on the other hand, place greater emphasis on user experience and innovation. Quality standards may be more focused on aspects such as product performance, appearance, and usability. To meet the needs of different consumers, manufacturers need to customize quality standards that align with specific product characteristics, while adhering to general standards and taking into account market trends and consumer feedback.

Implement effective quality control processes

In the electronics industry, implementing a comprehensive and efficient quality control process is crucial to ensuring that products achieve excellent quality at every stage, from design to delivery.

Effective quality control (QC) should not be limited to the production stage, but should run through the entire lifecycle of the product, from the initial design concept to the final production and delivery. Every step needs to be carefully controlled.

Integrated quality control from design to production

The tentacles of quality control should extend to the product design stage as early as possible.

By utilizing advanced design tools and simulation technology, manufacturers can predict and identify potential design flaws or performance issues. Identifying and addressing these issues early on can prevent costly losses during the production process due to improper design, such as rework, scrap, or customer returns.

Quality control during the design phase also encompasses the evaluation of raw material selection, production process feasibility, and product maintainability, ensuring that the design meets both market demands and production realities.

Establish a quality control team

A well-trained and experienced quality control team is crucial for monitoring quality during the production process.

They should possess profound industry knowledge and professional skills, and undergo regular training to stay familiar with the latest industry standards, quality testing methods, and troubleshooting techniques. Through continuous learning and practice, the quality control team can keenly detect any abnormal signals in the production process, quickly and accurately identify the root cause of problems, and take effective measures to resolve them.

Their existence provides a strong guarantee for the stable operation of the production line and the continuous improvement of product quality.

Quality control in supply chain: supplier selection and audit

The quality of raw materials and components serves as the foundation for determining the quality of the final product. Therefore, manufacturers must exercise caution when selecting suppliers, conducting a comprehensive evaluation based on various factors such as suppliers' historical quality records, production capacity, and quality management systems. Choosing reputable and reliable suppliers as partners is the first step towards ensuring the quality of raw materials and components.

Selection is just the beginning, and regular supplier audits are equally important. Manufacturers should establish a comprehensive supplier audit mechanism to conduct on-site or remote audits of suppliers' production processes, quality management systems, and raw material sources on a regular basis. Through audits, potential quality issues or risks that may exist in suppliers can be identified in a timely manner, and they can be urged to make rectifications to ensure that suppliers always maintain a state that meets quality standards.

Challenges and Solutions in Electronic Quality Control

In the electronics industry, quality control serves as the cornerstone for ensuring product performance and is an indispensable aspect in the face of industry complexity and change.

In the design and manufacturing process of modern electronic products, numerous challenges emerge endlessly, and manufacturers must employ advanced strategies and technologies to address these challenges and ensure the superior quality of their products.

Addressing the complexity in electronic design and manufacturing

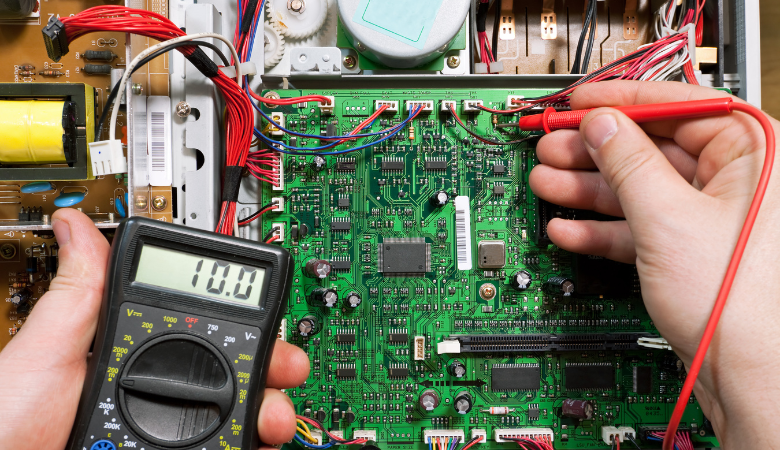

With the rapid advancement of technology, the design of modern electronic products is becoming increasingly sophisticated, and the application of micro-components is becoming more widespread, posing unprecedented challenges to quality control. These products have complex internal structures and high functional integration, and any minor defects can lead to the failure of the entire system. To address this challenge, manufacturers must rely on advanced testing technologies and methods.

For instance, high-precision automated testing equipment is employed, combined with intelligent algorithms and data analysis, to conduct comprehensive and precise inspections on every detail of the product. Simulation testing and virtual verification technologies are introduced to identify and address potential issues in advance during the design phase, thereby reducing quality risks in the production process.

Overcome the challenges in high-mix, low-volume production

In a highly mixed, low-volume production environment, with a wide variety of products and frequent changes, maintaining a consistent quality level becomes a challenging task. The production model demands that the quality control system must possess high flexibility and adaptability, capable of swiftly adjusting to cater to the unique characteristics and requirements of different products. To this end, manufacturers need to establish an intelligent quality control platform, integrating real-time data monitoring, automatic parameter adjustment, and a rapid feedback mechanism.

Managing quality control of global supply chains

The supply chain for electronic products spans multiple regions and countries, involving numerous suppliers. In this complex supply chain system, maintaining consistent quality standards poses a significant challenge. Manufacturers must establish a rigorous and comprehensive supplier management system to ensure that all suppliers adhere to the same quality standards and specifications. This includes regularly auditing and evaluating suppliers, inspecting their production processes, quality management systems, and sources of raw materials. Manufacturers should also establish close partnerships with suppliers, sharing quality control experience and technology to continuously improve the quality level of the entire supply chain.

END

The future of quality control in the electronics industry will increasingly rely on automation, artificial intelligence, and data-driven decision-making. These technologies will continue to enhance the speed, accuracy, and efficiency of the quality control process.

To implement effective quality control in the electronics industry, manufacturers must integrate quality control into every aspect of production, utilize advanced technology, provide continuous training, and maintain good cooperative relationships with suppliers. By doing so, they can ensure that products meet high standards, satisfy customer needs, and remain competitive in the market.