Quality control is very important in consumer electronics quality control. It ensures that products work well and meet customer expectations. Identifying and resolving issues early helps save money and reduce waste. Quality control also adheres to regulations, maintains your reputation, and builds trust.

In producing electronics for consumers, being careful and precise is key. Paying close attention enhances production speed and guarantees product functionality. Implementing smart methods can lead to long-term success and satisfied customers.

Set Up a Quality Management System (QMS)

Set clear quality goals and rules

Start quality control by setting clear goals and rules. These rules guide how you make your products. They help ensure every product works well and is reliable. First, list the key features your products must have. Then, create goals to measure progress, like lowering defect rates or improving assembly.

Write down these rules in detail. Share them with your team so everyone knows what to do. Check and update the rules often to match new technology or customer needs. This helps keep your products high-quality over time.

Follow industry rules and get certifications

Following industry rules builds trust and keeps your business credible. Many electronics industries need special certifications to show they meet safety standards. Learn about the rules for your industry and location. Some places may focus on environmental safety, while others care about electrical safety.

Make a checklist to track these rules during production. Teach your team to follow the rules carefully. Do regular checks to ensure your work meets the standards. You can also hire outside experts to review your processes. Staying certified avoids legal trouble and makes your business more respected.

Train Your Workforce for Consumer Electronics Quality Control

Teach your team about quality control regularly

Your team is key to keeping product quality high. Regular lessons help them learn new tools and testing methods. Start by making a training plan with topics like inspections, using tools, and fixing problems.

Use hands-on activities to teach real skills. For example, create practice situations where workers find and fix mistakes. This helps them feel confident and solve problems better. Pair new workers with skilled ones for guidance. This way, they learn faster and follow good habits.

Hold training often and keep it updated. Technology changes quickly in electronics. Teach your team the newest ways to test and fix products. Share resources like guides, videos, and online lessons. When your team stays informed, they can always produce great results.

Build a team that values responsibility and accuracy

Make sure every worker knows their role in quality control. Explain their tasks and how their work affects the whole process.

Reward workers who pay close attention to details. Praise those who meet quality goals. Share success stories in team meetings to inspire others to do well.

Create a space where workers feel safe sharing problems. If they spot issues early, you can fix them quickly. Use tools like suggestion boxes or feedback meetings to hear their ideas. Their input can improve your testing and fixing methods.

By encouraging responsibility and accuracy, your team will take pride in their work. This means fewer mistakes, smoother production, and better products.

Implement Incoming Quality Control (IQC) Processes

Check the quality of materials and parts

Your product's quality depends on the materials you use. Start by carefully inspecting all incoming materials. Look for flaws, damage, or anything unusual. Use tools like rulers, magnifiers, or special testers to check if items meet your standards.

Make a checklist for inspections. Include things like size, weight, and how well it works. This makes sure every batch is checked the same way. Teach your team to use this checklist during inspections. Finding problems early saves money and avoids bigger issues later.

Work with suppliers who provide good-quality parts. Better parts mean fewer problems and more reliable products. Always check that materials match your needs before accepting them.

Work with suppliers to keep quality steady

Good relationships with suppliers help ensure consistent quality. Share your quality rules with them and explain what you expect. This helps them understand your needs and deliver properly.

Meet with suppliers often to talk about their work and fix issues. Give feedback on their materials and suggest ways to improve. Open communication helps both sides aim for the same goal—providing quality parts for your products.

Ask for samples from new suppliers before placing big orders. Test these samples using your inspection process to ensure they meet your standards. This step reduces risks and ensures you work with trusted suppliers.

Tip: Keep track of supplier performance. Record things like delivery times, defect rates, and how quickly they respond. Use this information to find the best partners for your business.

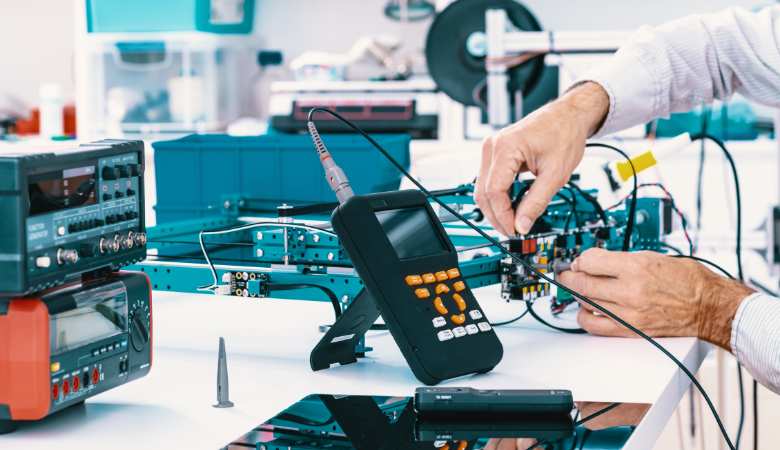

Leverage Automated Testing and Inspection Tools

Automated tools can change how you check product quality. They find defects faster, improve precision, and reduce mistakes. Adding these tools to your process keeps products reliable and customers happy.

Use Automated Optical Inspection (AOI) systems

AOI systems are important for electronics manufacturing today. These systems use cameras and smart software to check circuit boards. They spot problems like crooked parts, bad soldering, or missing pieces.

AOI systems test accurately without slowing production. They are great for making many products quickly, where manual checks might miss small issues. Place AOI systems at key points in your production line. This catches problems early, saves time, and ensures high-quality products.

Tip: Update AOI system software often. This helps them work with new designs and find harder-to-spot defects.

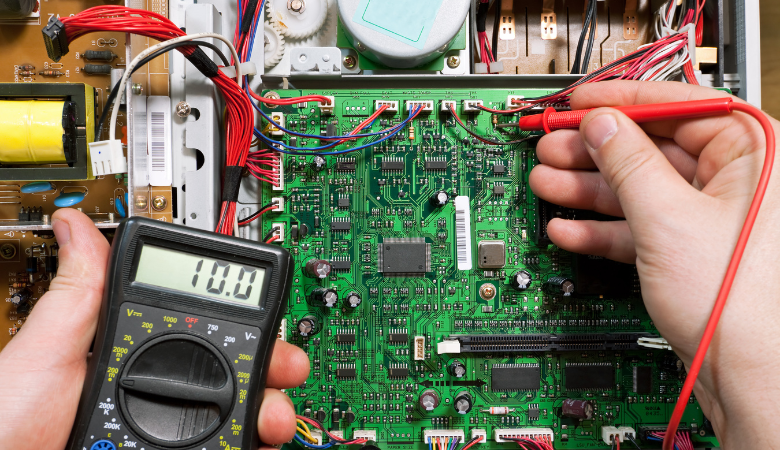

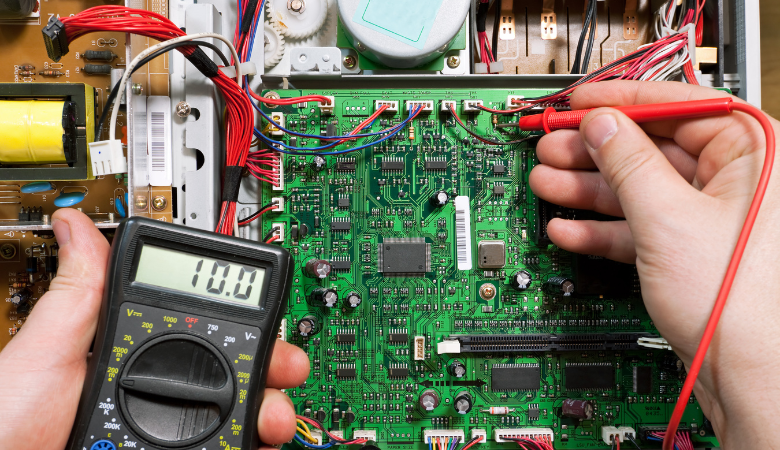

Integrate functional testing for complex electronics

Functional testing checks if electronics work as they should. It tests the whole product, not just single parts. For example, it checks if a circuit board powers up or connects to a network.

Adding functional testing helps confirm that complex electronics are reliable. Use automated tools to mimic real-world use. This finds problems before customers get the product.

Make a checklist for functional testing to stay consistent. Include things like power, connections, and signals. Teach your team to read test results and fix issues. By focusing on functional testing, you deliver dependable products and earn customer trust.

Note: Combine functional testing with AOI systems for better quality control. This ensures your products look good and work perfectly.

Monitor Production Data for Quality Control

Track key performance indicators (KPIs)

Tracking KPIs shows how well your process is working. These numbers help measure the success of quality control. First, decide which metrics matter most for your work. Examples include defect rates, production times, or first-pass yield.

Set up a system to collect and check these numbers often. Use tools like dashboards or software to see data live. This helps you find problems fast and fix them quickly. For instance, if defect rates go up, you can look for the cause right away. Regularly check your KPIs to keep the data correct and useful.

Share KPI results with your team so they stay updated. When workers see how their actions affect results, they improve their work. Use KPIs to guide decisions and keep quality high.

Use data analytics to identify trends and improve processes

Data analytics helps you find patterns in your production process. By studying the data, you can spot trends that are hard to see. For example, you might find more defects during certain shifts or with specific materials.

Use this knowledge to fix problems and stop them from repeating. Predictive analytics can also warn you about future issues. For instance, if a machine shows wear, plan repairs to avoid delays.

Always test changes to make sure they improve results. Encourage your team to use data to make their work better. Over time, this method will create a smoother and more reliable process.

Tip: Combine data analytics with regular checks to stay on track. This makes your quality control system even stronger.

Schedule Regular Testing and Audits

Regular testing and audits are key to keeping quality high. They help find problems, improve processes, and meet industry rules.

Check your processes with internal audits

Internal audits help you review how well your processes work. Start by making a list of important quality steps. Use this list to check if your team follows the rules. Look for problems like poor training, broken tools, or testing mistakes.

Test your products often during production. Check them at different stages to catch problems early. For example, inspect soldering or test if circuit boards work. Write down what you find and share it with your team. This helps everyone know what to fix.

Ask your team to join in audits. They might notice hidden issues or suggest fixes. Use what you learn from audits to improve your quality steps. Over time, this will make your production smoother and more reliable.

Tip: Let different team members handle audits. This brings new ideas and keeps everyone involved in quality checks.

Get outside audits for fair reviews

Outside audits give an unbiased look at your processes. These experts can spot problems you might miss and share best practices.

Hire trained auditors who know electronics manufacturing. Show them your quality rules and testing steps. This helps them understand your goals and check your work better. Outside audits also ensure you follow industry rules, which builds trust.

Plan regular reviews with these experts. Use their advice to improve how you work. For example, if they find repeated issues, change your tests or work with better suppliers. Their tips can help you stay ahead and make great products.

Note: Save reports from outside audits. These show your focus on quality and can help with certifications or customer questions.

Embrace Continuous Improvement Practices

Find and fix the main cause of repeated problems

Repeated problems can slow production and hurt product quality. To fix them, figure out what's causing the issue. Start by collecting information about the problem. Check production records, test results, or customer complaints. This helps you see when and where the issue happens.

Use tools like the "5 Whys" to dig deeper. Keep asking "Why?" until you find the real cause. For example, if a circuit board breaks, ask why it broke. If the answer is bad soldering, ask why the soldering was bad. Keep going until you find the main reason.

After finding the cause, make a plan to fix it. Test your solution to make sure it works. Watch the process to ensure the problem doesn't come back. Fixing the root cause makes your work smoother and more reliable.

Tip: Write down what you learn and how you fix problems. This helps your team handle similar issues in the future.

Get ideas from your team and support creativity

Your team is important for making things better. Ask them to share ideas and report problems. Set up ways to collect their thoughts, like suggestion boxes or team meetings. When workers feel listened to, they work harder and care more.

Reward workers who come up with helpful ideas. For instance, if someone finds a quicker way to test products, thank them. This inspires others to think of new solutions too.

Hold brainstorming sessions where your team can work together on ideas. Use their suggestions to improve how you check quality. Over time, this builds a workplace where everyone wants to improve.

Note: Review team feedback often and use the best ideas. This shows you value their input and want to make things better.

Using these quality control methods helps electronics manufacturing succeed long-term. Focusing on quality checks lowers defects and boosts efficiency. It also ensures reliable products, happier customers, and a stronger reputation.

Start now by checking your processes and using these tips. Review your progress often and make changes to stay on track. Staying dedicated to quality will bring better results and grow your business.

FAQ

What is the main purpose of quality control in electronics manufacturing?

Quality control makes sure your products work well and meet customer needs. It lowers defects, saves money, and follows industry rules. By focusing on quality, you create dependable products and earn customer trust.

How often should you conduct internal audits?

Plan internal audits often, like every month or three months. Regular checks help find problems early and improve your work. Change how often you audit based on how big or complex your production is.

Tip: Switch team members for audits to get new ideas and find hidden issues.

Why is training your workforce important for quality control?

Training gives your team the skills to spot and fix problems. It helps them understand quality rules and use tools correctly. Regular lessons keep them updated on new tools and methods, leading to better results.