The electronics industry requires improved precision and reliability in its products. Traditional methods of quality control in electronics industry often fall short when dealing with intricate designs and rapid production cycles. Artificial intelligence (AI) is revolutionizing this process by enabling companies to enhance their products. By leveraging data, AI identifies errors, inspects products, and ensures consistent standards. These advanced tools streamline production, making it faster and more accurate. As a result, AI is transforming the approach to quality control in electronics industry.

Traditional Challenges in Quality Control in Electronics Industry

Manual Inspection Limitations

Checking products by hand has been a key part of quality control. But it struggles to meet the speed of today's production. People inspecting products can get tired and miss small mistakes. This leads to uneven results and lower product quality. Manual checks also can't handle large-scale production well.

Note: Human limits in accuracy show why automated tools are needed for better quality control.

Complexity of Modern Electronics Designs

Today's electronics have tiny parts and detailed designs. These make spotting problems during production harder. Inspectors need special skills and tools to check layered circuits. As designs get more advanced, old methods can't handle the details. This can lead to faulty products being sold to customers.

Unordered List:

• Tiny parts are tough to check by hand.

• Layered circuits need better imaging tools.

• Old methods can't keep up with new electronics trends.

High Costs and Inefficiencies

Older ways of quality control cost a lot of money. Hand inspections need trained workers, which raises expenses. These checks also take a long time, slowing production. Companies lose time and money, hurting profits and growth. Using outdated methods stops businesses from using their resources wisely.

Tip: Cutting costs and speeding up processes are key to staying ahead in the electronics industry.

Advancements in AI Technologies for Quality Control

Machine Learning for Defect Detection

Machine learning is now key to improving quality control. It studies large amounts of data to find defects in electronics. These systems get better over time by learning from past data. They help find tiny flaws that people might miss during checks.

For instance, machine learning can scan circuit board images. It spots problems like bad soldering or parts out of place. This reduces mistakes made by humans and keeps quality steady. Also, it helps companies adjust to new designs by retraining the system to find new issues.

Tip: Using machine learning improves quality and cuts waste by catching problems early in production.

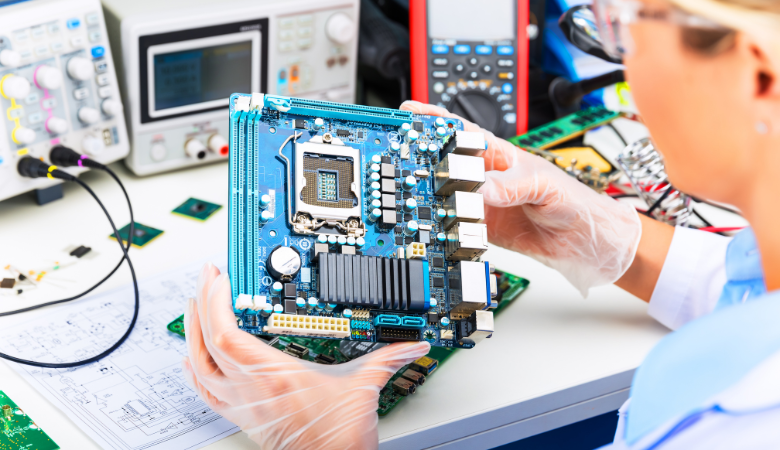

Computer Vision for Automated Inspections

Computer vision has changed how inspections are done in electronics. It uses smart cameras and AI to check products with great detail. High-quality cameras take clear pictures of parts, and AI finds any defects.

Unlike people, computer vision works fast and fits big factories. It checks complex designs, like layered circuits, without losing accuracy. For example, it can spot missing parts, scratches, or wrong placements instantly. This ensures every product meets strict quality rules before being sold.

Companies like computer vision because it grows with their needs. It handles more production without needing extra workers, saving money.

Predictive Analytics for Proactive Quality Management

Predictive analytics helps stop problems before they happen. It looks at old and live data to predict future issues. This lets companies fix things early, avoiding delays and bad products.

For example, it watches machines during production. If something seems wrong, it warns workers to fix it. This keeps quality steady and makes machines last longer.

Predictive analytics also helps companies follow market trends. It studies what customers want and helps adjust production plans. This keeps products competitive and high-quality.

Note: Predictive analytics helps companies act early, improving efficiency and quality.

Benefits of AI in Quality Control

Improved Accuracy and Precision

AI makes inspections more accurate by removing human mistakes. Machine learning studies large amounts of data to find defects. It spots problems that older methods often miss. These systems adjust to new electronics designs, keeping quality steady.

AI-powered computer vision helps with precision. High-quality cameras find tiny flaws like scratches or misaligned parts. This ensures every product meets strict quality rules before being sold.

Note: AI tools learn from data and improve over time. They are essential for smarter manufacturing processes.

Enhanced Efficiency and Cost Savings

AI speeds up production by automating repeated tasks. Computer vision tools replace manual checks, making inspections faster. Predictive analytics finds problems early, reducing waste and saving time.

AI also lowers costs. It reduces the need for skilled workers to inspect products. Cloud-based systems let companies monitor production from anywhere, saving money. These systems grow easily to handle more production without extra resources.

Unordered List:

• Faster checks using AI tools.

• Lower costs with automated systems.

• Flexible systems for growing factories.

Real-Time Monitoring and Feedback Systems

AI helps watch production in real time to ensure quality. Sensors collect live data, and AI finds problems right away. This stops small issues from becoming big ones, keeping quality high.

AI feedback systems give useful tips to improve production. For example, cloud systems show detailed reports about defects. This helps teams work together to fix problems and improve processes.

Tip: Real-time monitoring helps catch problems early. This improves product quality and reduces delays.

Challenges in Using AI for Quality Control

High Starting Costs and Needed Resources

Setting up AI systems costs a lot of money. Companies need to buy advanced tools, software, and hire skilled workers. Factories may also need upgrades to use smart quality systems. These high costs can make it hard for smaller businesses to use AI.

Training AI takes a lot of data and computer power. Companies must gather and process big datasets to make AI work well. This can take time and cost a lot, especially for businesses with fewer resources.

Tip: To save money, companies can use cloud-based tools and focus on strong cybersecurity.

Fitting AI into Current Systems

Adding AI to old factory systems can be tricky. Older machines often don't work well with new AI tools. Companies may need to make big changes to connect AI with their equipment.

Moving old data to AI systems is another problem. Transferring data from older tools can be hard and might cause mistakes. Without smooth integration, important information for quality checks could be lost.

Unordered List:

• Old systems may not match with AI tools.

• Moving data can be slow and error-prone.

• Production might slow down during system updates.

Ethical Issues and Job Concerns

Using AI raises worries about job loss. Automated systems mean fewer workers are needed for inspections. Companies should train workers for new jobs that work alongside AI.

Keeping AI systems safe from hackers is also important. AI uses a lot of data, which can be targeted by cyberattacks. Companies must protect this data to keep their quality systems secure.

Note: It's important to balance new technology with fairness to workers for long-term success in quality control.

Future Advancements in Quality Control Technologies

Autonomous AI-Driven Quality Control Systems

Autonomous AI systems are the future of quality control. These systems work on their own, using smart programs to find defects. They check products in real time and adjust to changes. This reduces mistakes and makes production faster.

For example, these systems can quickly scan circuit boards. They find tiny flaws that older methods might miss. They also learn from past data to keep quality steady. As they improve, they will change how factories manage quality checks.

Edge AI and IoT Integration

Edge AI and IoT are making quality control faster. Edge AI works on local devices, so it doesn't need the cloud. This means quicker decisions and real-time monitoring. IoT devices, like smart sensors, collect data from machines to help improve production.

For example, a sensor can notice temperature changes in a machine. Edge AI studies this data right away and warns workers of problems. This helps make better products and keeps machines working longer.

Blockchain for Transparent Quality Assurance

Blockchain is becoming important for clear quality checks. It keeps a secure record of every step in production. This helps track materials, check processes, and meet quality rules.

This openness builds trust with buyers and partners. For instance, blockchain can prove a phone’s parts meet quality standards. As more companies use blockchain, it will improve quality control in many industries.

AI has changed how electronics companies manage product quality. It fixes problems and brings new ideas to the process. AI improves accuracy, speeds up work, and lowers costs. This helps businesses stay ahead of competitors. As technology grows, AI tools will change how quality is checked. Companies using AI will meet future needs with better products. They will also have an advantage in selling reliable items to customers.

FAQ

What does AI do in quality control for electronics?

AI helps by automating checks, finding flaws, and predicting problems. It uses tools like machine learning and computer vision to make inspections faster and more accurate. This keeps product quality steady.

How does computer vision make inspections better?

Computer vision uses smart cameras with AI to study products closely. It quickly finds issues like scratches, missing parts, or wrong placements. This makes inspections faster and more reliable than manual checks.

Can small electronics companies use AI?

Small companies may struggle with AI due to high costs. But cloud-based AI tools and flexible systems make it easier. These options let smaller businesses use AI without spending too much on upgrades.