In the field of clothing and footwear manufacturing, quality is the key to winning the market and establishing brand credibility. With the increasing global competition and rising consumer expectations, ensuring that products meet high-standard quality requirements has become a top priority for footwear and clothing manufacturers. It helps manufacturers identify potential issues, prevent the outflow of defective products, and also promotes transparency and efficiency throughout the supply chain.

This article will explore the third party inspection services that shoe and clothing manufacturers must understand, and how these services can help enterprises improve product quality and enhance market competitiveness.

Third party inspection, as a professional and independent service form, refers to the comprehensive and meticulous inspection, testing, or certification activities carried out by a third-party professional institution that is completely independent of both the buyer and seller of the product, in accordance with international/domestic relevant standards, industry norms, technical specifications, or contract requirements agreed upon in advance by the buyer and seller, for various types of products. In the fashion and practical industry of footwear and apparel, the service scope of third party inspection is extremely extensive, and it extends to every key link in the product life cycle - from the procurement and warehousing of raw materials, to the monitoring of semi-finished products during the production process, to the comprehensive quality inspection of the final finished products, all of which are covered. This service aims to ensure that footwear and apparel products not only meet high standards in quality, but also meet the stringent requirements of the market and consumers in terms of safety, environmental protection, and various performance indicators.

Compared to the quality control activities carried out internally by the enterprise - internal inspection, third party inspection demonstrates its unique value and advantages. Internal inspection is usually carried out by the enterprise's own quality control team, which focuses more on real-time monitoring of the production line and daily quality management to ensure smooth production processes and that products meet established standards. However, due to its internal nature, internal inspection may have certain limitations in terms of objectivity and fairness.

In comparison, third party inspection stands out for its high degree of independence, professionalism, and authority. Since third party inspection agencies do not have a direct interest relationship with either the buyer or the seller of the product, they can provide more objective and impartial evaluation results. These results not only provide reliable quality certification for both parties, but also play a crucial role in product transactions, market access, and building consumer trust. In addition, third party inspection agencies usually have rich industry experience and professional technical teams, and can provide comprehensive and professional inspection services for footwear and apparel manufacturers based on the latest industry standards and regulatory requirements, helping enterprises improve product quality and enhance market competitiveness.

At the front end of shoe and clothing manufacturing, material inspection is a crucial step. Third party inspection agencies conduct rigorous quality, composition, and safety testing on all incoming raw materials, including but not limited to fabrics, leather, and accessories. This process aims to ensure that the materials used comply with industry standards and specific customer requirements from the source, avoiding subsequent production failures or product quality hazards caused by material issues. Through advanced testing technology and professional analysis, third party inspection agencies can accurately identify potential defects in materials, such as insufficient strength, poor color fastness, and the presence of harmful substances, thereby providing customers with reliable material quality certification.

Sample approval is another crucial step in pre-production inspection. A third party inspection agency will conduct a comprehensive and detailed evaluation of the design samples, covering multiple dimensions such as appearance, size, functionality, and wearing comfort. By comparing with design requirements and market standards, the inspection agency can promptly identify deficiencies in design or issues with poor market adaptability, and offer suggestions for improvement. This process not only ensures the reasonableness of product design but also greatly enhances the market competitiveness of the product after it is launched.

During the production process, a third party inspection agency will regularly visit the production line for on-site inspections to ensure that the production process strictly follows the quality control plan. By observing the production environment, checking equipment status, supervising employee operations, etc., the inspection agency can promptly identify potential issues in the production process and assist the company in taking prompt corrective measures. This dynamic supervision approach effectively reduces production deviations and ensures the stability of product quality.

During the production process, the third party inspection agency also conducts sampling inspections on key indicators such as product size, color, and sewing process. Through professional inspection equipment and strict inspection standards, the inspection agency can accurately determine whether the product meets the specification requirements, timely detect and correct deviations in production. This refined inspection method ensures that every product meets the standards expected by customers.

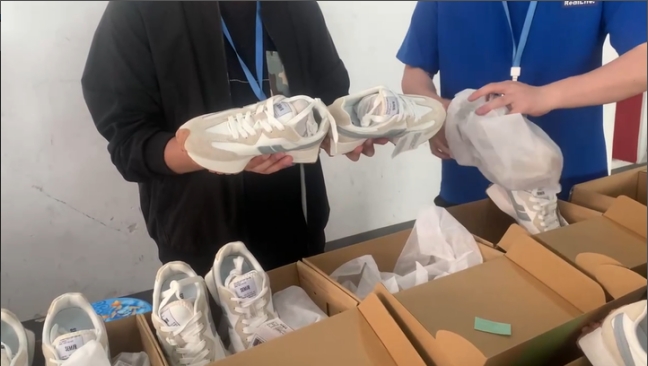

Before the product is about to leave the factory, a third party inspection agency will conduct a comprehensive quality inspection of the finished product. This process covers various aspects such as appearance inspection, functional testing, and durability testing, aiming to ensure that the product has no obvious defects and meets the needs of the market and consumers. Through professional inspection procedures and strict quality standards, the inspection agency can provide customers with reliable proof of the quality of the finished product, laying a solid foundation for the product to be launched on the market.

In addition to the quality of the product itself, packaging and labeling are also important aspects that consumers pay attention to. Third party inspection agencies will carefully verify packaging materials, label information, barcodes, etc., to ensure that all information is accurate and meets regulatory requirements. This step not only enhances the professional image of the product but also avoids market confusion or consumer complaints caused by incorrect information.

Before shipment, a third party inspection agency will check whether the packaging is suitable for long-distance transportation, including the robustness of the packaging, moisture and dust resistance, etc. By simulating various possible scenarios during transportation, the inspection agency can evaluate the protective capabilities of the packaging to ensure that the products are not damaged during transportation. This step effectively reduces transportation risks and guarantees the safe delivery of products.

Before shipment, the third party inspection agency will also verify the packaging and labeling information again to ensure it is completely consistent with the order. This step is not only a review of the previous work but also a confirmation of the final state of the product. Through a rigorous verification process, the inspection agency can ensure that the product is presented to consumers in the best condition and with the most accurate information.

In the field of footwear and clothing manufacturing, product defects and the risk of returns are important factors that constrain the development of enterprises. The intervention of third party inspection services is like building a solid defense line for product quality. Through material inspection and sample approval in the early stages of production, comprehensive monitoring during the production process, and quality inspection of the final finished products, third party inspection agencies can detect and correct various problems in production early. This whole-chain quality control model effectively reduces the rate of defective products, thereby minimizing the production of defective products and greatly reducing the risk of returns, saving costs for enterprises and improving customer satisfaction.

In the fiercely competitive footwear and apparel market, product consistency and standardization are crucial for companies to win the trust of consumers. Third party inspection agencies ensure that every batch of products meets the same high-quality standards through strict quality inspection standards and processes. Whether it's product size, color, material, sewing craftsmanship, or functional testing, third party inspection can provide precise data support and feedback, helping companies adjust production parameters in a timely manner to ensure product consistency and standardization. This not only enhances the market competitiveness of the products but also establishes a good brand image for the company.

In the footwear and apparel manufacturing industry, the accuracy of delivery time is directly related to the reputation of the company and the satisfaction of customers. Third party inspection agencies effectively monitor production progress, keep track of the operation status of the production line in real time, and promptly identify and resolve bottlenecks in production. At the same time, through close communication and cooperation with the company, third party inspection can also assist the company in formulating reasonable production plans and delivery schedules, ensuring that products are delivered on time and strictly adhere to deadlines. This efficient production monitoring and planning management capability not only enhances the production efficiency of the company but also strengthens customer trust and reliance on the company.

In today's era where consumers are increasingly focused on product quality, products that have undergone third party certification undoubtedly possess greater market competitiveness. As independent, impartial, and professional third-party institutions, the inspection reports and certification certificates issued by third party inspection agencies possess high authority and credibility. When products have undergone third party inspection and obtained certification, consumers can purchase and use these products with greater peace of mind, as it signifies that the products have undergone rigorous quality testing and evaluation. This enhanced consumer trust and confidence not only boosts the sales and market share of enterprises but also establishes a good reputation and brand image for the enterprises, laying a solid foundation for their long-term development.

When selecting a third party inspection service provider, the primary consideration is whether they possess professional qualifications and certifications in the relevant field. These qualifications and certifications, such as ISO/IEC 17025 laboratory accreditation, ISO 9001 quality management system certification, etc., are not only a reflection of the inspection agency's professional competence but also strong evidence of its impartiality, accuracy, and reliability. Therefore, it is imperative to carefully verify the qualification certificates and certifications of the inspection agency to ensure that it has the ability to provide professional inspection services for footwear and clothing products.

Experience and reputation are important factors that cannot be ignored when choosing a third party inspection service provider. By reviewing the inspection agency's service duration in the footwear and apparel industry, successful cases, customer feedback, etc., one can gain a comprehensive understanding of its professional capabilities, service quality, and market recognition. At the same time, it is also possible to consult with experts, peers, or trade partners in the industry to listen to their opinions and suggestions, in order to more accurately assess the strength and credibility of the inspection agency.

Different footwear and clothing products have varying demands for inspection services. Therefore, when selecting a third party inspection service provider, special attention should be paid to its service scope and flexibility. An excellent inspection agency should be able to provide comprehensive inspection services ranging from raw material inspection, production process monitoring to finished product quality inspection, packaging, and label verification. At the same time, it should also have the ability to customize personalized inspection schemes according to customer needs, in order to meet the inspection requirements of different products, markets, and standards.

To find a trusted partner for footwear and clothing inspection, you can start within the industry. Consult with industry associations, peers, or trade partners to learn about the inspection agencies they recommend or those they have previously worked with. These recommendations are often based on actual cooperation experiences and word of mouth, and have high reference value, which can help you quickly locate high-quality inspection resources.

After initially screening out several potential inspection partners, it is recommended to personally visit these institutions for on-site inspection and evaluation. By visiting the laboratories of the inspection agencies, understanding the operational processes, observing the advancement of facilities and equipment, and communicating with inspection personnel, you can gain a deeper understanding of the professional capabilities, management level, and service attitude of the inspection agencies. This hands-on inspection method can provide you with a more intuitive and authentic basis for cooperation, ensuring the reliability of the selected inspection agency.

In third party inspection services, the issuance of inspection reports is often influenced by various factors, resulting in the inability to present the reports immediately. This is mainly due to the complexity of the inspection process and the size of the sample. Inspection agencies need to strictly follow the established inspection standards and procedures to conduct meticulous testing and analysis of the samples, ensuring the accuracy and reliability of the inspection results. For the inspection of a large number of samples, more time and resources are required. When seeking third party inspection services, customers should fully understand and accept the potential delays that may exist in the inspection reports, so as to reasonably arrange production plans and delivery times, avoiding unnecessary troubles caused by report delays.

During the process of third party inspection services, effective communication with suppliers and manufacturers is crucial to ensure the smooth progress of the inspection work. Differences in inspection standards, processes, and product characteristics may lead to different understandings of certain inspection details between both parties. It is necessary for the inspection agency and the client to establish a close communication mechanism, through regular exchanges, meetings, or training, to ensure that both parties have a common understanding of inspection standards, processes, and expected results. Only in this way can misunderstandings and conflicts caused by poor communication be avoided, ensuring the smooth progress of the inspection work and the accuracy of the inspection results.

High-quality inspection services often come with higher costs, determined by the complexity, professionalism, and the richness of resources required for the inspection process. For clients, how to plan a budget reasonably while ensuring the quality of inspection has become a problem that needs careful consideration. Firstly, clients should clarify their inspection needs and objectives, select suitable inspection items and standards, and avoid unnecessary waste. Secondly, they can communicate fully with inspection agencies to understand the cost differences of different inspection plans, so as to make the optimal choice according to their budget. Finally, clients should also incorporate inspection costs into their overall production and operation costs, conduct long-term budget planning and management, and ensure that every investment brings the greatest value return.

With the advancement of technology and the continuous changes in consumer demands, third party inspection services will also continue to evolve, placing more emphasis on environmental protection, ethical compliance, and the application of intelligent inspection technology.

For footwear and apparel manufacturers, choosing and cooperating with a professional and reliable third party inspection agency will be a key step towards achieving long-term sustainable development.

With the continuous improvement of industry standards and the complexity of the international trade environment, the value of third party inspection services will become more prominent, becoming an indispensable part of the quality control system in the footwear and apparel industry.

For footwear and apparel manufacturers, keeping up with the development trend of third party inspection services and continuously optimizing the quality control system will be the key to winning the future market.

The Smart Sourcing Content Team is committed to delivering high-quality, easy-to-understand information that helps our audience navigate the complexities of global sourcing. Our team of writers has extensive experience in producing articles across various fields such as procurement, supply chain management, market trends, and industry best practices. We specialize in sectors like apparel, textiles, and consumer goods, providing targeted insights to help businesses in these industries optimize their sourcing strategies and stay competitive.